AMS-71PA Automated Vane Ultrasonic Phased Array Inspection System

Fast, easy and safe ultrasonic automated inspection of wind turbine blades, AMS-71PA provides you with fast, efficient and safe quality assurance of blade structural integrity. Inspection systems will increase production speed and reduce production costs.

Better quality, faster production and lower costs We know that blade quality is the key to determining the ultimate long-term performance of wind turbine blades. AMS-71PA will make quality assurance of your blade structural integrity easier and more efficient. The system is designed for vertically oriented blades. Unique full-size multichannel probe array, 21 phased array probes (unconventional), enabling your inspection speed up to 3 m/s.

Functional characteristics

advantage

advantage

• Efficient single person operation

• High detection speed

• Unique phased array probe line array

• High resolution data collection

• Thoroughly inspect the blades in the vertical direction

• Autonomous operation, self powered

• Integrated coupling medium recycling

application

AMS-71PA is an automatic scanning device for blade beams of wind turbines. It is designed specifically for inspecting 200/400mm beams.

The scanner is installed on a forklift for inspection, and the wind turbine blades are placed vertically. This inspection involves parallel scanning along the length direction of the blade using the multi focus rule.During inspection, the forklift is driven by the operator in the direction of the blades. The operator positions the scanner unit in the correct position (height) with the help of a video monitor. The scanner unit is installed on a robotic arm to make contact between the probe and the surface of the blade and compensate for the distance changes.

AMS-71PA includes a scanner unit connected to an electric telescopic arm system through a balance ring joint. The boom is installed on the forklift tower hanger. This tower is used to lift the scanner to the required height.

The auxiliary equipment required for the operating system is installed on the cabinet at the front of the forklift. Forklifts provide power for the inspection system, so external power is not required for scanning operations.

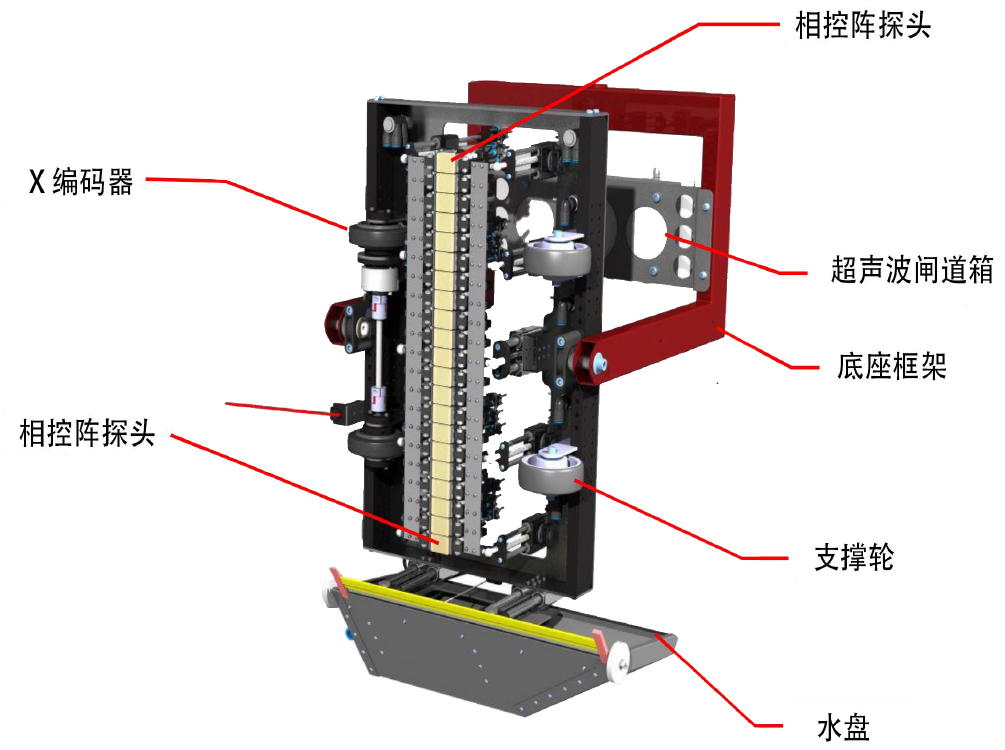

The scanner unit consists of a hanging array consisting of 21 phased array probes (non conventional probes). The framework is connected to the basic framework through two horizontal nodes. The base frame is connected to the telescopic arm through vertical joints.

The two sets of joints and three contact wheels on the universal joint frame ensure that the scanning system unit aligns with the blade surface when moving near it.

Technical Parameter

|

Height x width x length |

2.6x1.3x2.8 m |

|

weight |

3 ton |

|

Scanning method |

X-axis moving scanning, full coverage |

|

Ultrasonic testing technology |

21 Phased array probes (non conventional probes) |

|

Scan length |

unlimited |

|

Scan width |

500mm(customizable 800mm) |

|

Scanning speed |

3 M/S |

|

check the accuracy |

3*10mm(customizable 1.5*2.5mm) |