AMS-37 Ring Forging Mobile Ultrasonic Automatic Inspection System

Fast, easy and safe flange ultrasonic automatic inspection

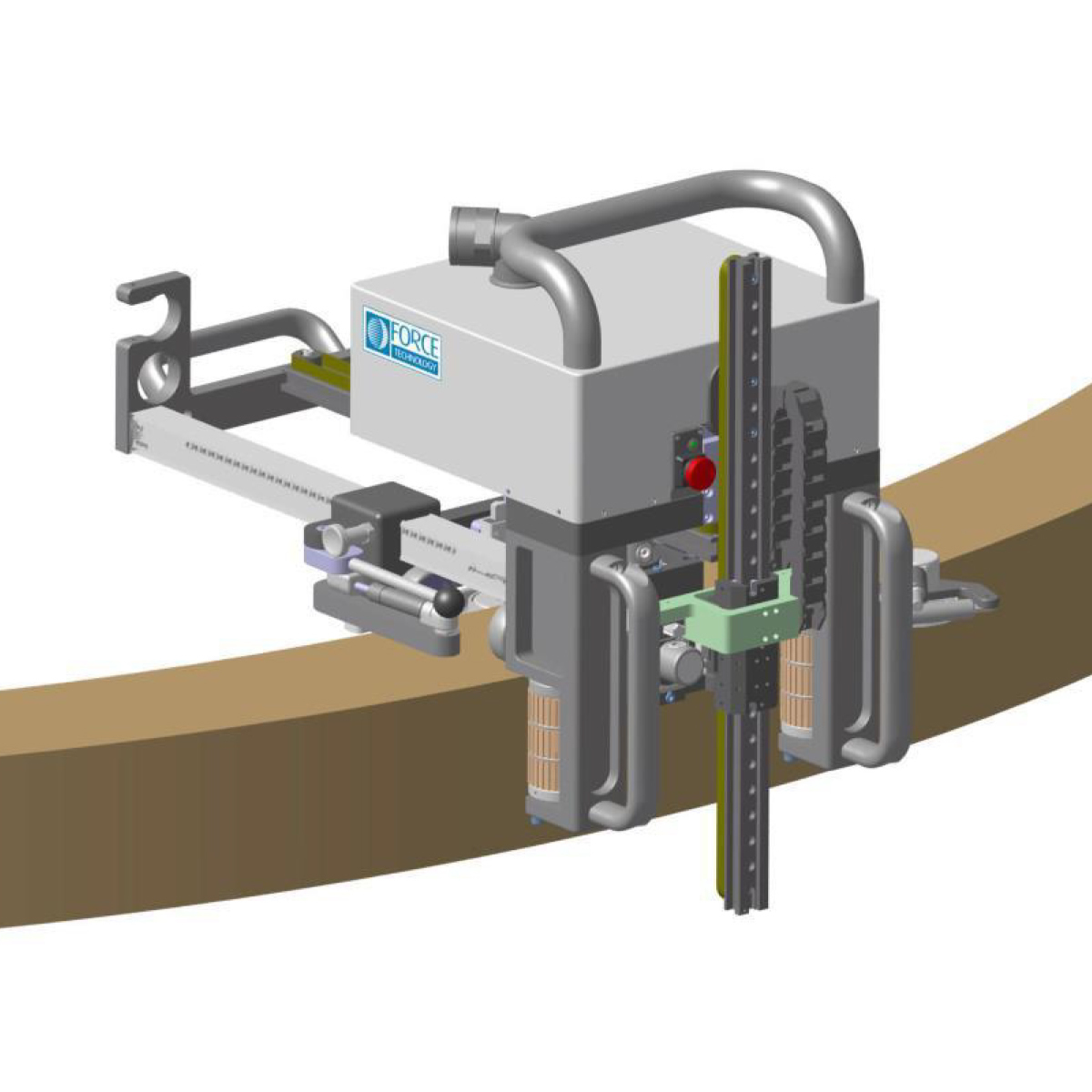

The AMS-37 Ring Scanner is a dedicated ring inspection. It is a very convenient and effective tool in the manufacturing workshop because it moves this small size scanner to a ring, which is easier and faster than moving the ring to an immersion slot scanner.

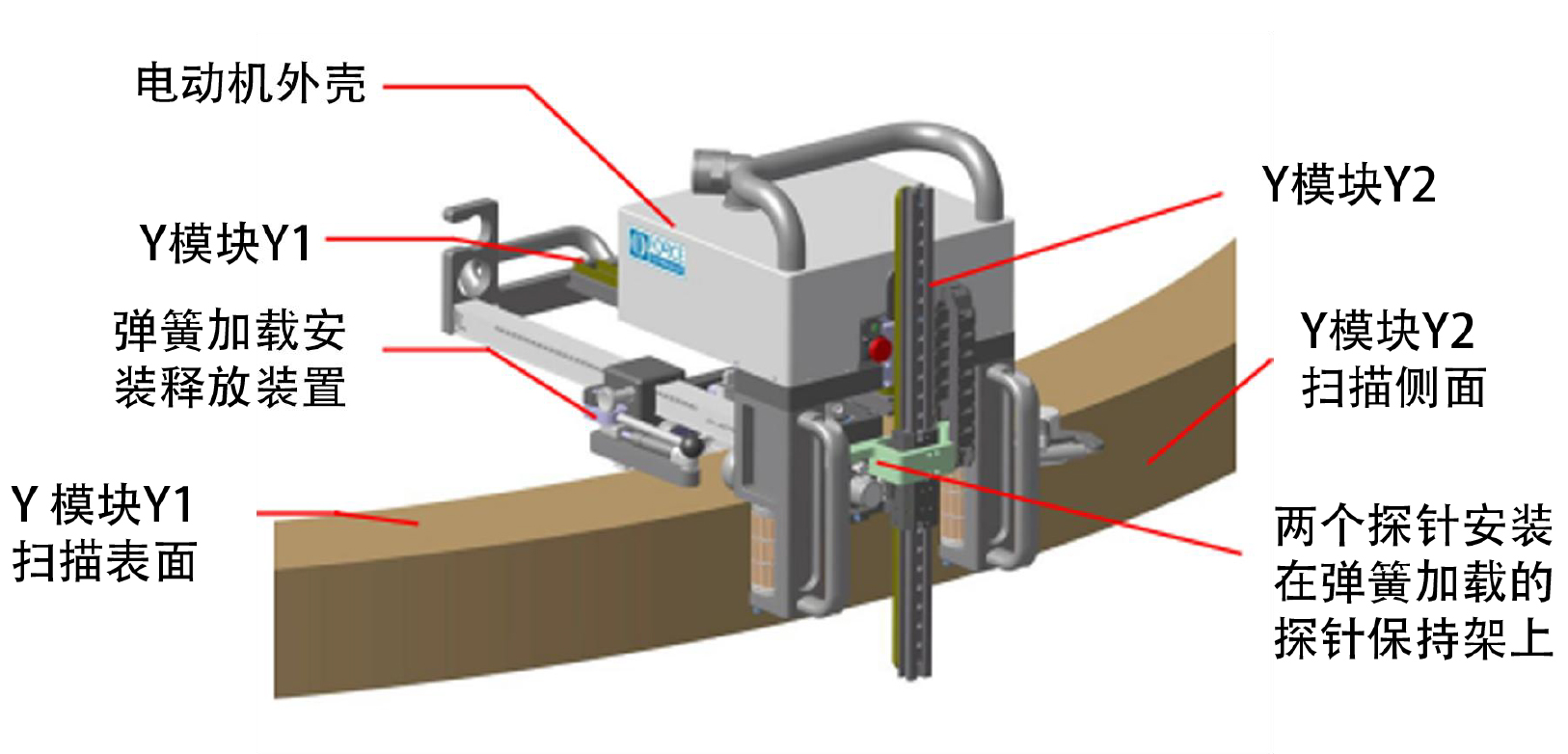

Identify the two Y-modules, Y1 and Y2, both equipped with two probe holders that enable two probes on each Y module to be examined. The two Y modules are individually controllable, so the difference in height and thickness is not important.

The probe holder is mounted separately in the probe holder frame, and the two probes are moved and adapted to the surface separately, ensuring that the most important constant contact between the probe and the surface is maintained as much as possible.

Functional characteristics

characteristic

• The ASM-37 detection system meets the detection requirements for circular forgings with a height of 100-350mm, an outer diameter of 2500-450mm, and a thickness of 150-300mm;

• In addition to specifying the size of the workpiece, users emphasize that most workpieces can only undergo single crystal double-sided testing. Suggest changing the B4S probe to a ceramic hard contact surface probe, which is more suitable for automated ultrasonic testing;

• At present, ASM-37 is matched with 4 probes (single crystal probe or double crystal probe), and it is not advisable to consider the overall stability and reliability of the system in terms of mechanical motion when increasing the number of probes.

• The movement speed of the Y-axis is 150mm/sec

Identify two Y modules Y1 and Y2, both equipped with two probe brackets for inspection of the two probes on each Y module. These two Y modules are individually controllable, so the difference in height and thickness is not important.

The probe bracket is installed separately in the probe bracket frame, with two probes moving and adapting to the surface, ensuring as much important and constant contact as possible between the probe and the surface.

Detection speed

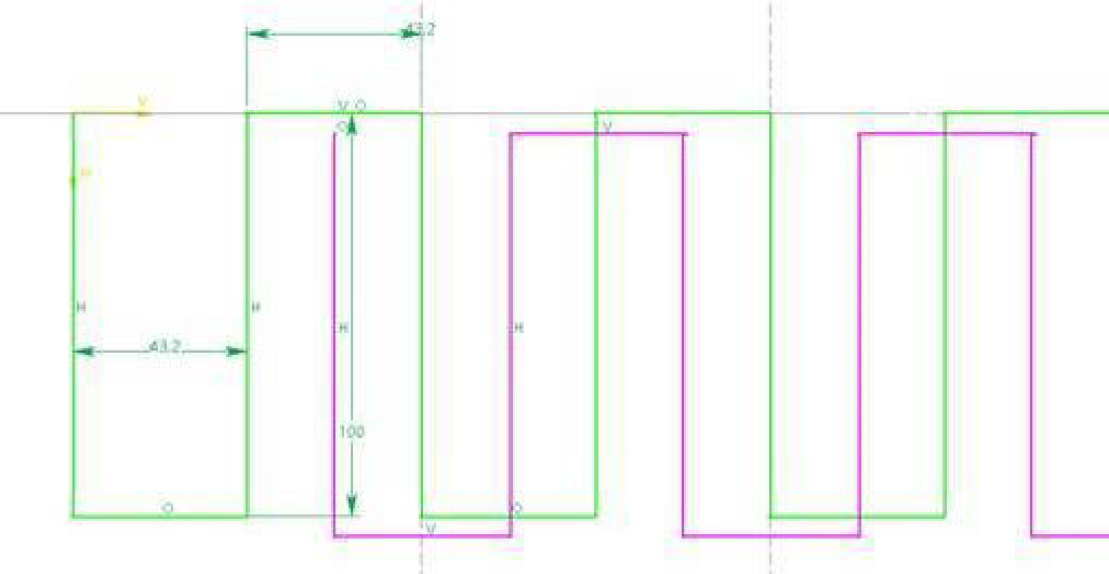

Double sided single crystal probe scanning, with 10% probe coverage, the scanning method is shown below:

• The probe chip size is 24mm, with a 10% probe coverage of 21.6mm, and the effective scanning of two probes is 43,2mm;

• A complete scan for 5 seconds;

• Taking the inner diameter of 3900mm, outer diameter of 4500mm, and height of 350mm as an example, the detection time is 27.2 minutes;

![]()

• There are two probes on each surface of both surfaces.