DEMA70A Magnetic Crawl Corrosion Thickness Gauge System

This system does not require scaffolding, no need to polish the anti-corrosion layer, and no couplant, and can realize the rapid detection of high-altitude wall thickness corrosion through the remote control system.

• Equipped with electromagnetic ultrasonic thickness probe for rapid screening and positioning of wall thickness corrosion.

• Intensive and accurate scanning of suspected corrosion areas to quantify wall thickness corrosion.

• A-scan and B-scan display as standard.

• With a video camera, it can observe the video situation of the inspected surface in time.

• Remote control (handle) is used to remotely control the scanning track, and the scanning trajectory can be preset.

Functional characteristics

Product Features of Two Wheel Magnetic Crawler

Advanced instruments that can carry various non-destructive testing equipment have accumulated a large amount of on-site solution experience in various fields such as petrochemical, boiler special inspection, and power. Due to its ability to carry electromagnetic ultrasound for spot inspection or B-scan thickness measurement in areas with severe corrosion and erosion such as pipeline bottoms, elbows, or tees, it is known by industry experts as a divine tool for pipeline corrosion detection.

It has the following characteristics: exquisite structure, high flexibility, strong magnetic attraction, high control accuracy, advanced detection technology, compatibility with video detection, unique probe lifting mechanism, etc.

1) Exquisite structure and high flexibility:The compact and exquisite appearance design allows for convenient corrosion detection of various ferromagnetic pipelines and containers. Two wheel magnetic climb length 350mm × Width 140mm × With a height of 130mm and a weight of ≤ 5.5kg, the unique two wheel structure allows it to freely walk on pipelines with a minimum diameter of 125mm. The minimum turning radius is 400mm and can easily pass through bends with a minimum bending radius of 100mm. Therefore, the range of two wheel magnetic crawling motion and scanning has been greatly expanded.

2) Magnetic attraction super strong:

In terms of design, the two wheel magnetic crawler uses rare earth magnets to make high-strength permanent magnet wheels, and even in the event of accidental power outage, there is no risk of the vehicle body falling off the tested surface. Therefore, two rounds of magnetic crawling can safely perform scanning tasks with different postures such as horizontal, vertical, and inverted. The maximum vertical load is 5kg, which means that dragging a 5kg weight does not affect its various movements in the vertical direction at all.

3) High control accuracy:

The travel speed of the two wheel magnetic crawler is infinitely adjustable from 0-6m/min, and the function of setting the detection distance can be achieved through the cooperation of a precision encoder. It can be programmed on the controller and can work and check according to the required distance, greatly improving the efficiency and accuracy of detection.

4) Adopting advanced testing technology:

Adopting an advanced automatic crawling (electromagnetic ultrasound) wall thickness corrosion detection system, the detection accuracy is comparable to traditional piezoelectric ultrasound. Without the need for scaffolding, polishing anti-corrosion coatings, and any coupling agents, rapid positioning and screening of high-altitude pipe wall corrosion can be achieved through remote control on the ground, as well as precise measurement of dense scanning. While ensuring detection accuracy, it greatly improves detection efficiency and reduces detection costs.

5) Compatible video detection:

While conducting corrosion thickness testing on pressure pipelines, containers, and base materials, the two wheeled magnetic crawler can also be used for visual inspection of defects using its built-in visual lens. Alternatively, it can replace human eye recognition during high-altitude operations to determine the path and direction of travel, ensuring detection accuracy and results.

6.) Unique probe lifting technology:

When conducting corrosion point thickness or B-scan testing, it is essential to encounter mechanical actions that require the probe to be lifted. When detecting thickness at points, measurements need to be made at the specified same spacing points, and the data of each point is obtained when the probe falls on the surface being measured. Therefore, the probe's adjustable function can achieve the most accurate thickness value for each point. When performing B-scan on the tested object, although one probe is tightly attached to the surface, if there is a large weld seam clearance, the probe needs to be raised for crossing, so the lifting function of the probe is also very important.

Electromagnetic ultrasonic thickness measurement unit

Electromagnetic ultrasonic testing has low requirements for the surface of the workpiece, allowing for paint, coating, and unevenness on the surface. Compared to conventional ultrasound. Electromagnetic ultrasound has the following advantages:

• Non contact detection, no coupling agent required (lift up to about 4mm).

• Low surface requirements, capable of detecting rough surfaces with oxide skin, coatings, and other workpieces.

• Fast detection speed.

Functional characteristics

• No surface polishing required, can penetrate anti-corrosion coatings and floating rust, and does not require the use of coupling agents.

• The thickness measurement can penetrate up to 4mm thick surface corrosion, paint, anti-corrosion and other coatings, and the thickness value of the metal object displayed by the instrument does not need to be considered for calculating the coating thickness.

• The measurement of non verticality (the normal of the transducer/probe relative to the tested object) is as high as ± 25o, with low requirements for the verticality of the probe after placement.

• The thickness measurement results can be displayed in digital value format, A-scan format, time-based B-scan image format, and distance-based (encoder) B-scan image format.

• Adopting expert intelligent algorithms, it has three thickness measurement modes: automatic mode, single gate manual mode (single peak measurement), and double gate manual mode (peak peak measurement). Greatly reduces the impact of human factors and simplifies operational steps.

• Built in database for basic material shear wave velocity, and customizable shear wave velocity values.

• Directly issue inspection record sheets and thickness value lists for convenient data analysis and processing.

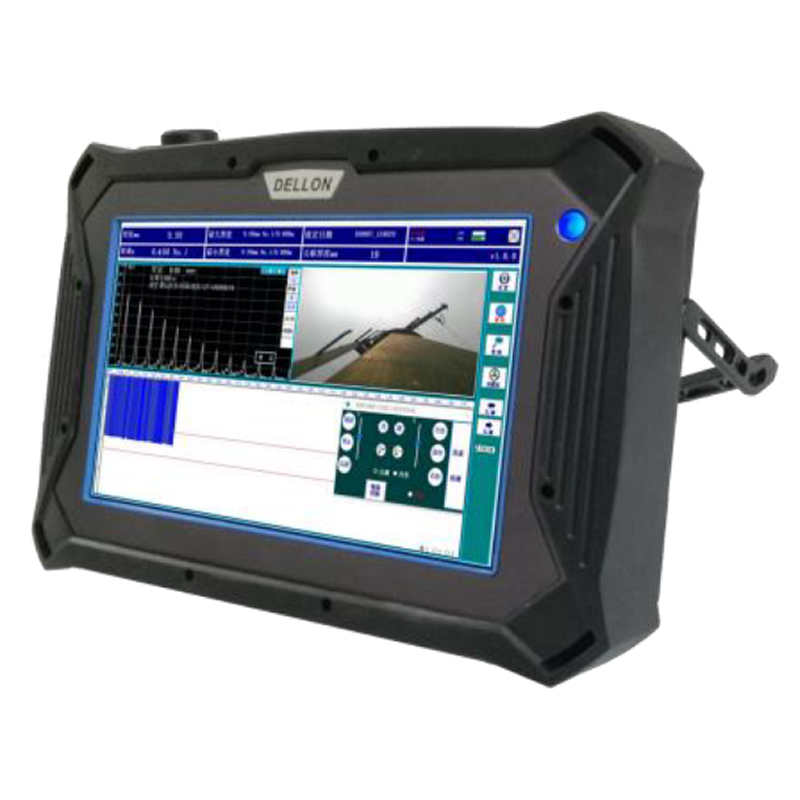

Measurement analysis software

• Simultaneously display thickness values, A, B scan results

• Directly issue inspection record sheets and thickness value lists for convenient data analysis and processing

• Compatible with Win7/10 (32/64 bit) operating system

Technical Parameter

|

Detection control cable (crawling distance) |

25m |

|

Thickness measurement |

accuracy 0.04mm、range2~100 mm(steel) |

|

Working clearance/lifting degree |

≥4mm |

|

Measurement of non verticality (normal of the transducer/probe relative to the tested object) |

±25o |

|

excitation frequency |

3.0MHz~5.0MHz |

|

Minimum curvature radius of the measured object surface |

|

|

When moving longitudinally |

≥50mm |

|

When moving in a circular direction |

≥125mm |

|

Sound speed range |

1000~9999 m/s、Adjusting the increment1 m/s |

|

operation temperature |

-20~+50℃ |