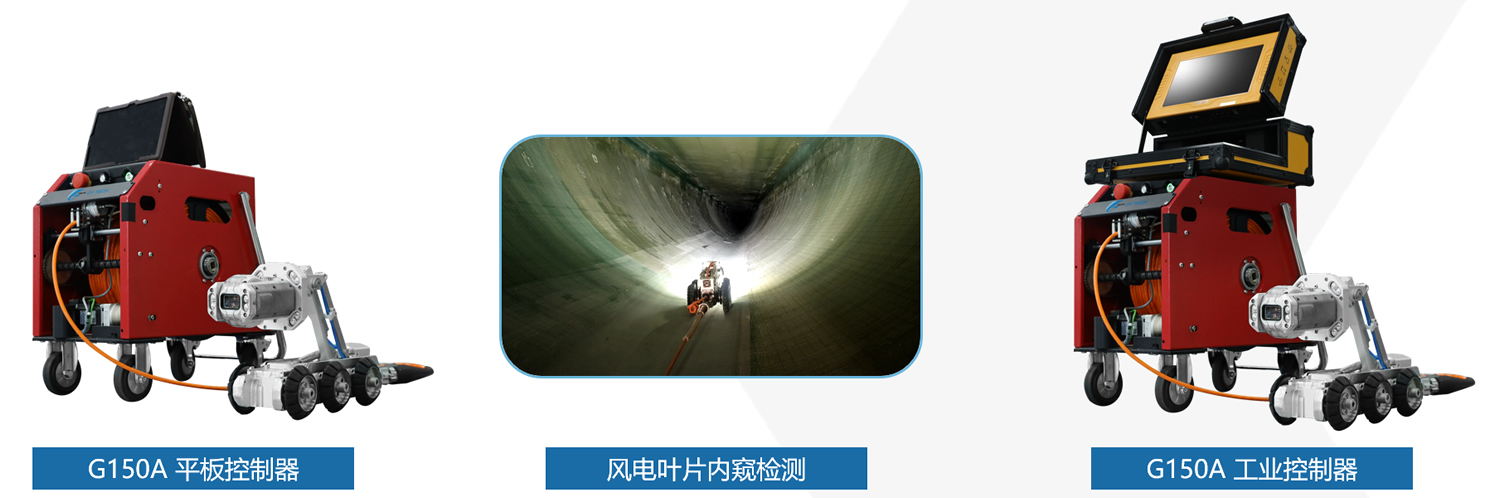

Wind turbine endoscope inspection robot G150A

G150A is mainly used for visual inspection of wind turbine blades, which can visually detect defects such as bulges, folds, degumming, and cracks inside the blades. The robot is compact and lightweight, with a long detection distance, reaching more than 85% of the blade length. G150A has super climbing and obstacle climbing ability, climbing angle up to 35°, multiple protection design, different wheel combination, can adapt to the complex situation inside the blade, and provide reliable video and image basis for the acceptance and maintenance of wind turbine blades.

The G150A can be used with two controllers, a flat panel controller or an industrial controller.

Functional characteristics

-

The advantages of digital transmission

The difference between digital transmission and analog transmission is as follows, and the biggest advantage of digital transmission is that it can achieve long-distance high-quality video transmission.

Characteristics of analog communication: In order to improve the signal-to-noise ratio, it is necessary to amplify the attenuated transmission signal in a timely manner during the signal transmission process, and the noise inevitably added during the transmission process is also amplified simultaneously. As the transmission distance increases, the accumulation of noise increases, leading to a serious deterioration of transmission quality.

Digital communication characteristics: Due to the limited discrete amplitude of digital signals (usually taking two amplitudes), although they are also affected by noise interference during transmission, when the signal-to-noise ratio deteriorates to a certain extent, the decision regeneration method is used at an appropriate distance to generate a digital signal that is the same as the original transmitter without noise interference, thus achieving long-distance high-quality transmission.

More scientific body design

G150A can easily enter DN150 pipes with repair or deformation

Equipped with a wheel set with a diameter of 70mm, there is no need to disassemble the lifting bracket, just remove the auxiliary light

Body size: 680mm (length) * 130mm (width) * 125mm (height), easy to access DN150 pipes.

High brightness LED light

Equipped with 8 bright LED main lights and 8 bright LED auxiliary lights, it can ensure sufficient light in the pipeline.

Optional 3 pairs of wheel sets, with only one screw required for tire disassembly, making it easy to replace on site. Different wheel diameters are configured according to different pipe sizes

DN150(70轮),DN200(100轮),DN300(130轮)

This robot has super strong climbing and obstacle crossing capabilities, multiple protection designs, and different wheel combinations, which can adapt to the complex internal conditions of the blades.

CMOS cameras with a front end of 2.1 million and 4 million pixels available for selection

Standard 210W pixel camera, optional 400W or above pixel camera as needed

The use of resistance wire heating to achieve lens defogging function

When the lens is found to have fog, you can click on the defogging function in the control software. The lens heating wire will be heated for 1 minute to remove fog. If it cannot be completely removed within 1 minute, you can continue to click on the defogging function to remove fog twice

More powerful lens: 3D tracking function of the lens

When we discover pipeline defects, the traditional approach is to lock the defect position by controlling the lens rotation, including 360 degree rotation and pitch rotation, which requires a certain amount of time.

Through the lens 3D tracking function, defects can be quickly locked. Simply click on the defect position on the screen, and the lens will automatically adjust the rotation angle for locking, simplifying operations and improving detection efficiency.

Laser width measurement helps operators quantify pipeline defects

By using two laser emission devices installed on the lens as a reference, when we need to measure, we turn on the laser through control software. Two parallel laser beams will hit the measured object, and the distance between the two laser points is a certain amount. The software algorithm can measure the size of pipeline defects.

The rear view 2.1 megapixel CMOS lens is equipped with two high-power LED lights to ensure clear visibility of the reversing image

During the reversing process, the wire is automatically wound up, and the winding speed is automatically adjusted according to the speed of the robot's retreat. The wire is automatically arranged to ensure that the cables are neatly arranged on the reel

power supply

Flexible configuration according to the scene

AC power generated by the generator on the directly connected engineering vehicle

For scenarios where it is not convenient for vehicles to enter, it can be paired with a lithium-ion battery with a capacity of 20Ah and a range of up to 8h

Optional controller

Tablet: Lightweight and easy to carry

Industrial controller: 13.3-inch high-definition screen, built-in cooling system, capable of adapting to high temperature environments (above 40 degrees Celsius), built-in battery (with a range of 1.5h)

Technical Parameter

|

Body dimensions |

680mm(long)*130mm(wide)*125mm(tall) |

|

Matching diameter |

70mm Wheel group |

|

Various wheel sets available |

DN150(70wheel),DN200(100轮),DN300(130wheel) |

|

Camera |

pre-210 Ten thousand pixels和400Choose from 10 megapixel CMOS cameras |

|

Cable car |

120m Cable car |

|

Industrial Controller |

|

|

High definition screen |

13.3cun |

|

Adapt to high-temperature environments |

Equipped with a cooling system, it can adapt to high temperature environments above 40 degrees Celsius |

|

Adapt to high-temperature environments |

Endurance1.5h |