Al honeycomb board and fiberglass honeycomb board phased array C-scan detection

1. background

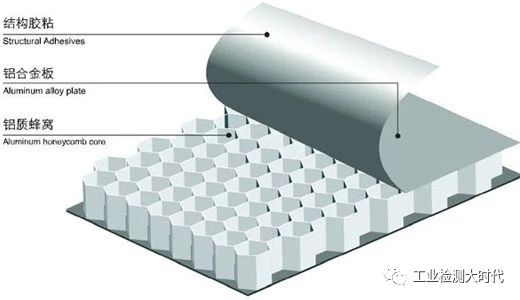

Composite materials with honeycomb structures were first used as important support structures in aerospace due to their high strength and compressive strength.

With the development of technology, honeycomb structural composite materials are also widely used in various fields, including railways, building decorations, ships, and so on.

Especially for the composite materials of Al skin/Al honeycomb structure, the center is made of aluminum hexagonal honeycomb, with a low density (approximately 3-7 kilograms per square meter), which is 1/5 of the weight of wood boards of the same thickness and area, 1/6 of glass, and 1/7 of aluminum, greatly reducing building load and cost. Due to the large amount of air in the middle interlayer, it can provide sound insulation (air sound insulation can reach 30dB), thermal insulation (thermal resistance can reach 0.02 (㎡· K/W)), and no combustible substances, The fire resistance rating reaches B1 level, which is waterproof, moisture-proof, and free from harmful gas release. It has a high specific strength and stiffness per unit mass (1.7 times the structural stiffness of the ribbed structure), and is not easily deformed.

The detection of honeycomb composite materials has always been a difficult point in testing. Previously, ultrasonic water spraying systems were mainly used for the detection of aerospace honeycomb composite materials, which were complex in structure, expensive in cost, and inefficient. They were generally only used in aerospace composite manufacturing enterprises to detect complex shapes and environments with high detection requirements.

This experiment uses a brand new ultrasonic phased array detection technology for detection, which is efficient, displays clearly, and has reliable detection results. The equipment or system cost is lower than that of the water spraying system, and is suitable for aerospace composite material repair and maintenance enterprises.

2. Configuration of detection equipment

Host:

Omniscan X3 phased array ultrasonic testing system

Probe: 5MHz, 64 chip wheel ultrasonic phased array probe.

3. Analysis of test results

Test block (1)

Material: aluminum skin/aluminum honeycomb core, skin thickness: 0.3mm

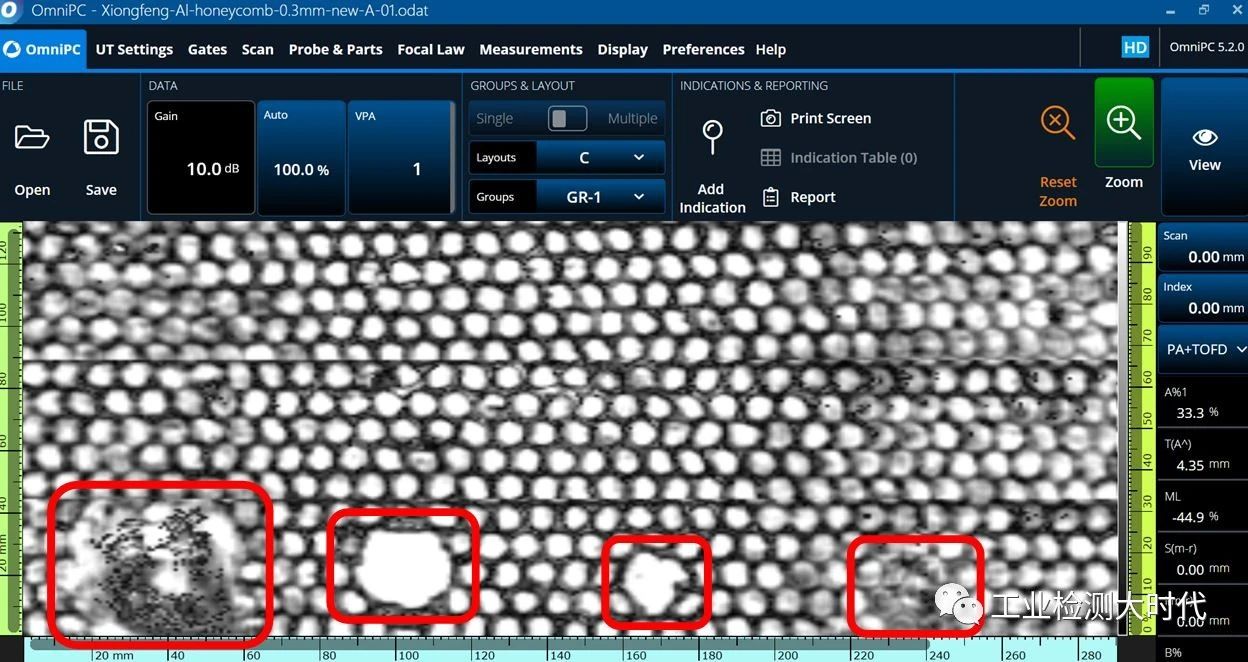

The inspection results of side A on test block (1) are as follows, where four artificial defects can be clearly seen and the honeycomb structure is clearly visible.

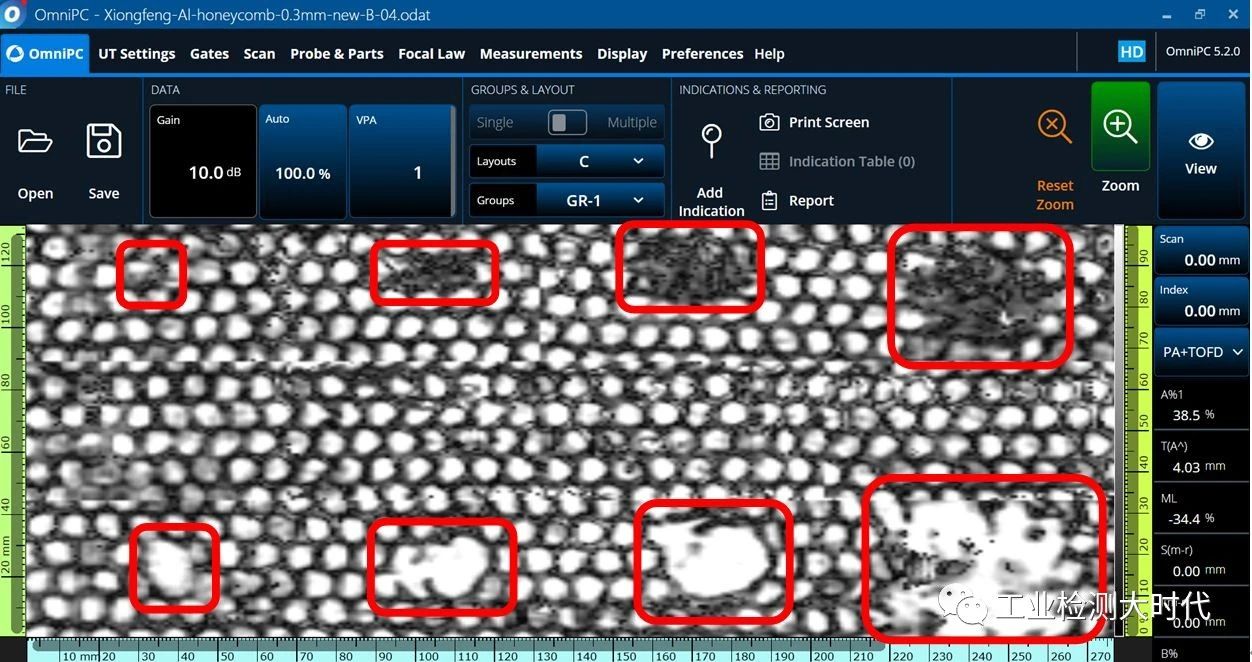

The inspection results of B-side on test block (1) are as follows, with 8 artificial defects clearly visible and the honeycomb structure clearly visible.

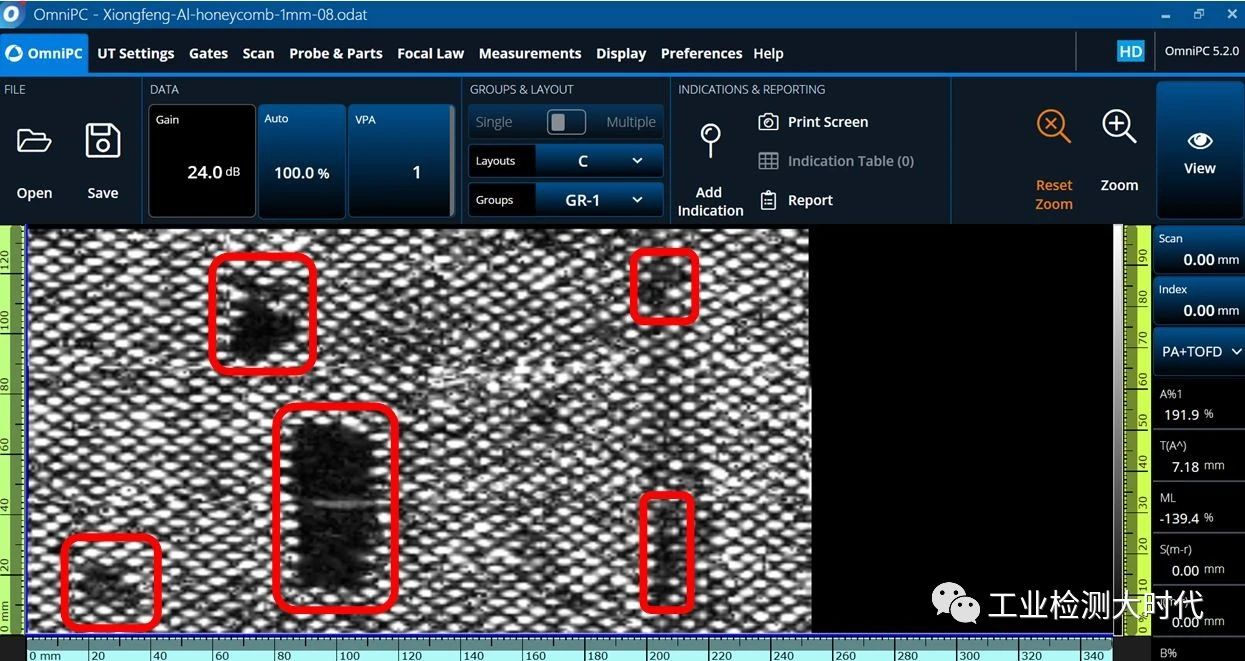

Test block (2) material: aluminum skin/aluminum honeycomb core, skin thickness: 1mm

The inspection results on test block 2 are as follows, and a clear honeycomb structure and internal artificial defects can also be seen.

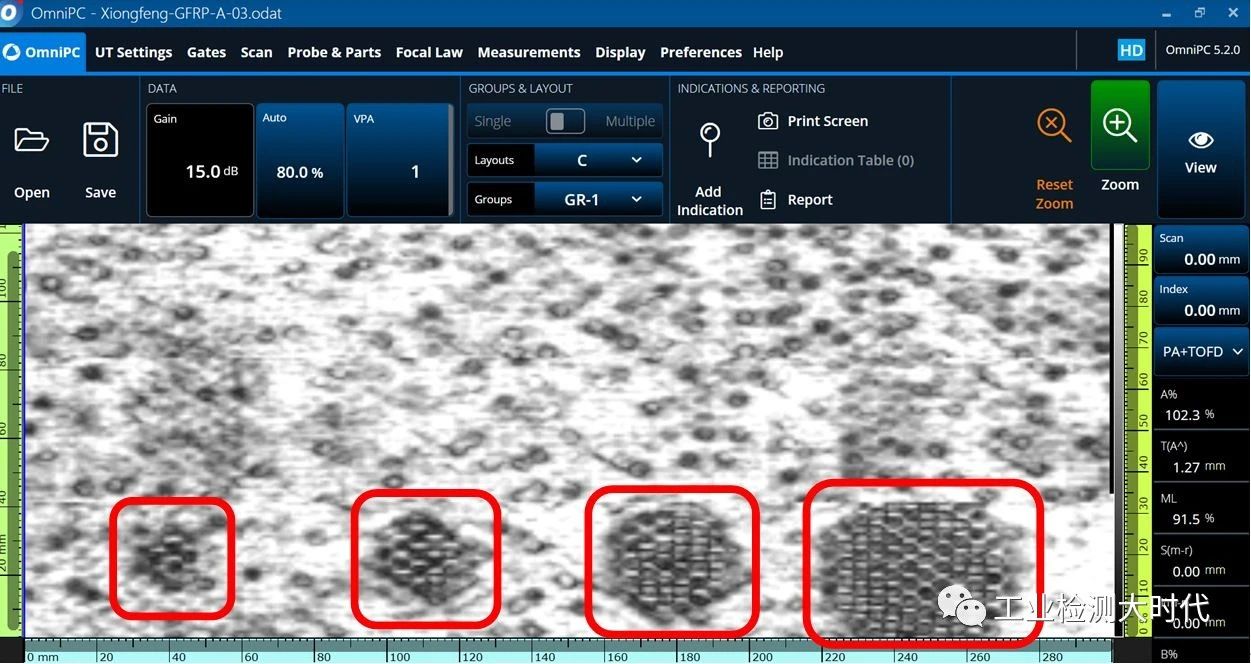

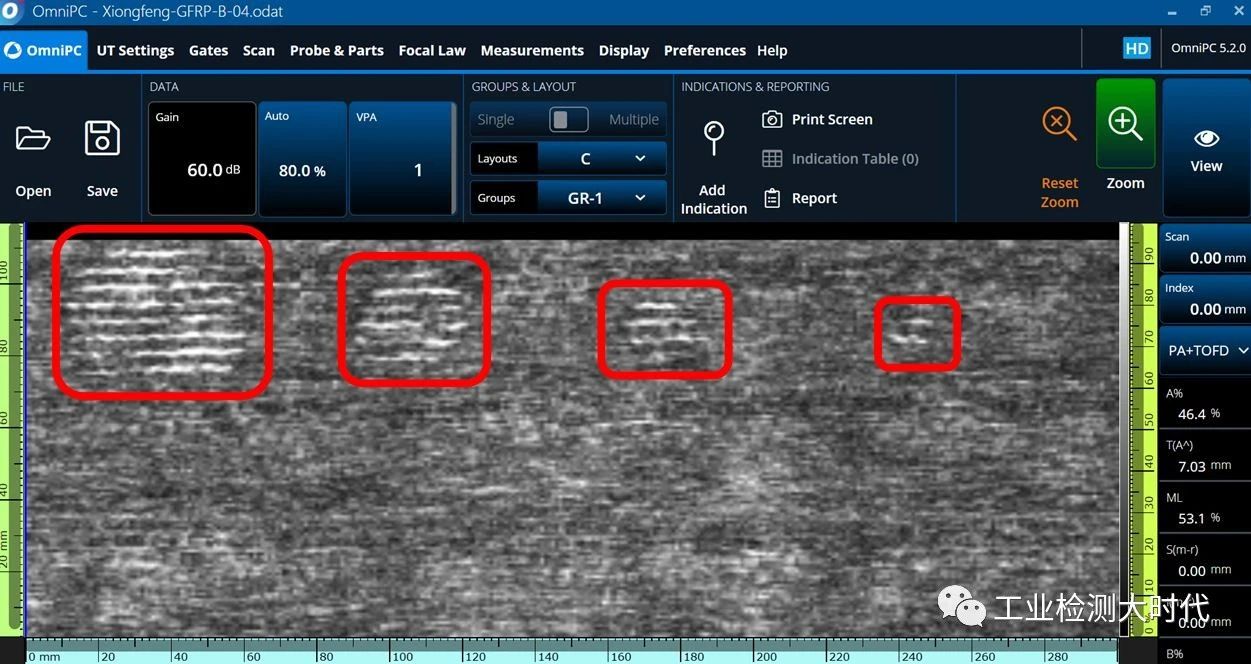

Test block (3) material:

Glass fiber reinforced polymer (GFRP) core structure, skin thickness: 0.3mm

The inspection results of side A on test block 3 are as follows, and four artificial defects can be clearly seen.

The inspection results of B-side on test block 3 are as follows, and four artificial defects can also be seen.

5. Conclusion

The use of ultrasonic phased array technology, combined with wheeled probes, can effectively detect the debonding of Al alloy honeycomb and GFRP honeycomb structural composite materials. The detection results are clear and reliable, and the complete structure of the hexagonal honeycomb can be observed, and it is sensitive to defects.