GSCAN-200 emerged with great success

preface

Bolts are widely used in the connection of components such as thermal power and wind power, and they need to withstand complex stress, temperature, and other effects during service, making them prone to fracture or failure. Their safety is increasingly valued by people. How to detect fatigue cracks in bolts without dismantling them is always a challenge. In theory, conventional ultrasonic testing methods can be used for the detection of fatigue cracks, but the detection space of in-service equipment is limited, the probe accessibility is poor, and the detection sensitivity is low. Therefore, the equipment needs to be stopped and the bolts need to be removed for inspection. Ultrasonic phased array technology is a new technology in the field of non-destructive testing, which can achieve a large angle range of scanning without moving the probe. It can achieve various views of defects for imaging, and the detection results are intuitive, making it easy to identify and judge defects. And this technology can detect workpieces with complex geometric shapes, which can be controlled by software to improve detection resolution, signal-to-noise ratio, and sensitivity.

1. Basic Theory

The detection principle of ultrasonic phased array technology is to change the phase relationship of each array element when it emits (or receives) sound waves reaching (or coming from) a certain point in the object by controlling the time delay of the excitation and reception pulses of each array element in the array transducer, achieving changes in the focal point and beam position, thereby completing the beam synthesis of the phased array and forming imaging scanning. Ultrasonic phased array technology can control the characteristics of the beam, scanning angle range, focusing depth, and focal size through software, thus greatly overcoming the detection limitations of conventional ultrasonic methods due to the directionality of the sound beam.

GSCAN 200 is a bolt specific phased array flaw detector developed and designed by our company in collaboration with universities, based on the principle of ultrasonic phased array detection for in-service and non in-service bolt detection. This machine has small size, light weight, strong hardware performance, complete software functions, and simple operation, making it the perfect choice for on-site testing!

3. Product Features

8.4 Color LCD touch screen

Available in 16/64 and 32/64 models

Equipped with AutoCAD advanced workpiece contour graphics loading module

Equipped with a dedicated probe for bolt detection

L also has conventional phased array detection function

Multiple display modes such as A/B/S/C/TOFD/offline 3D

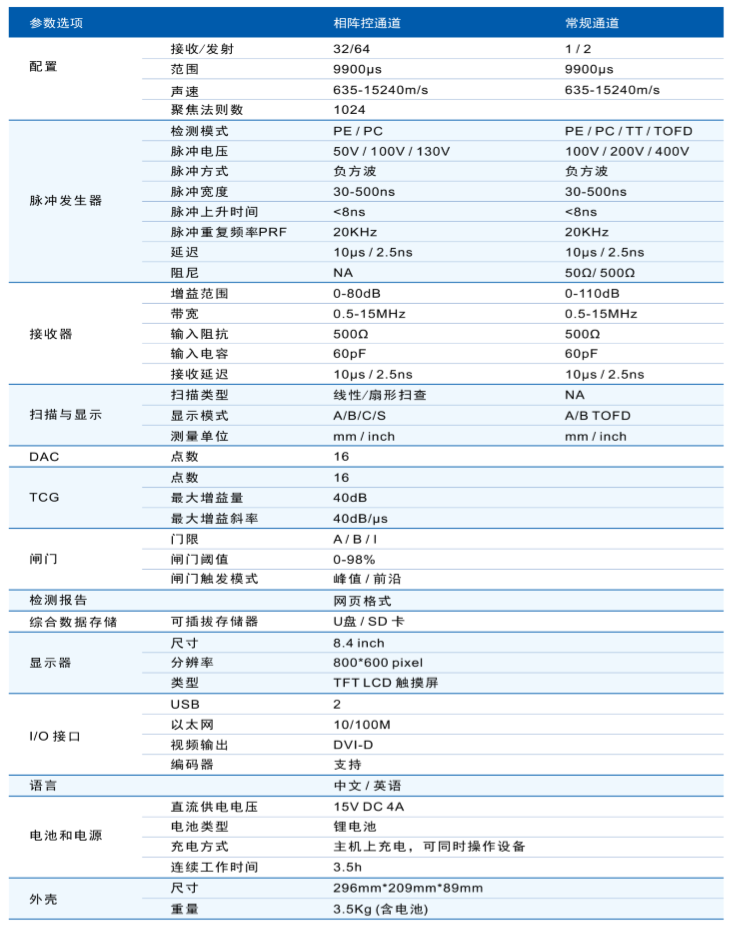

4. Performance indicators

5. Application Scenarios

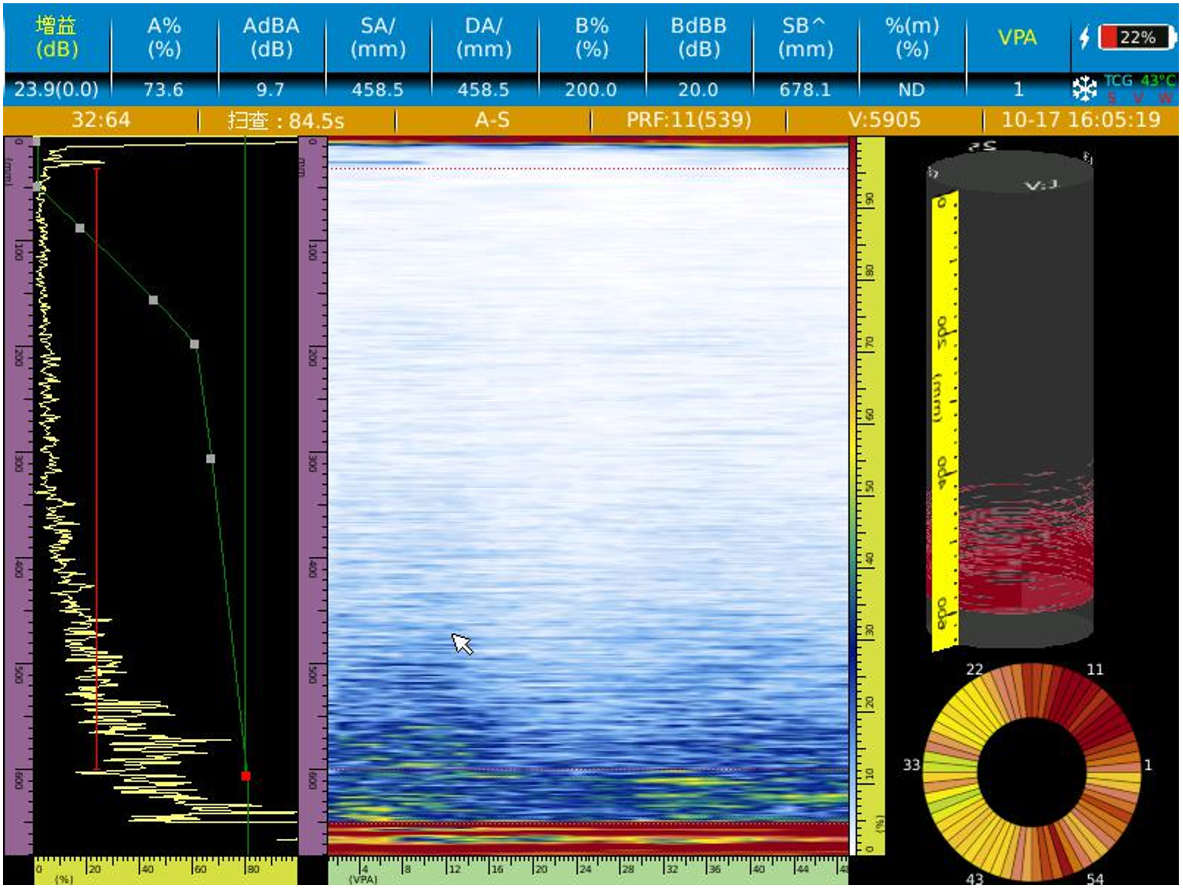

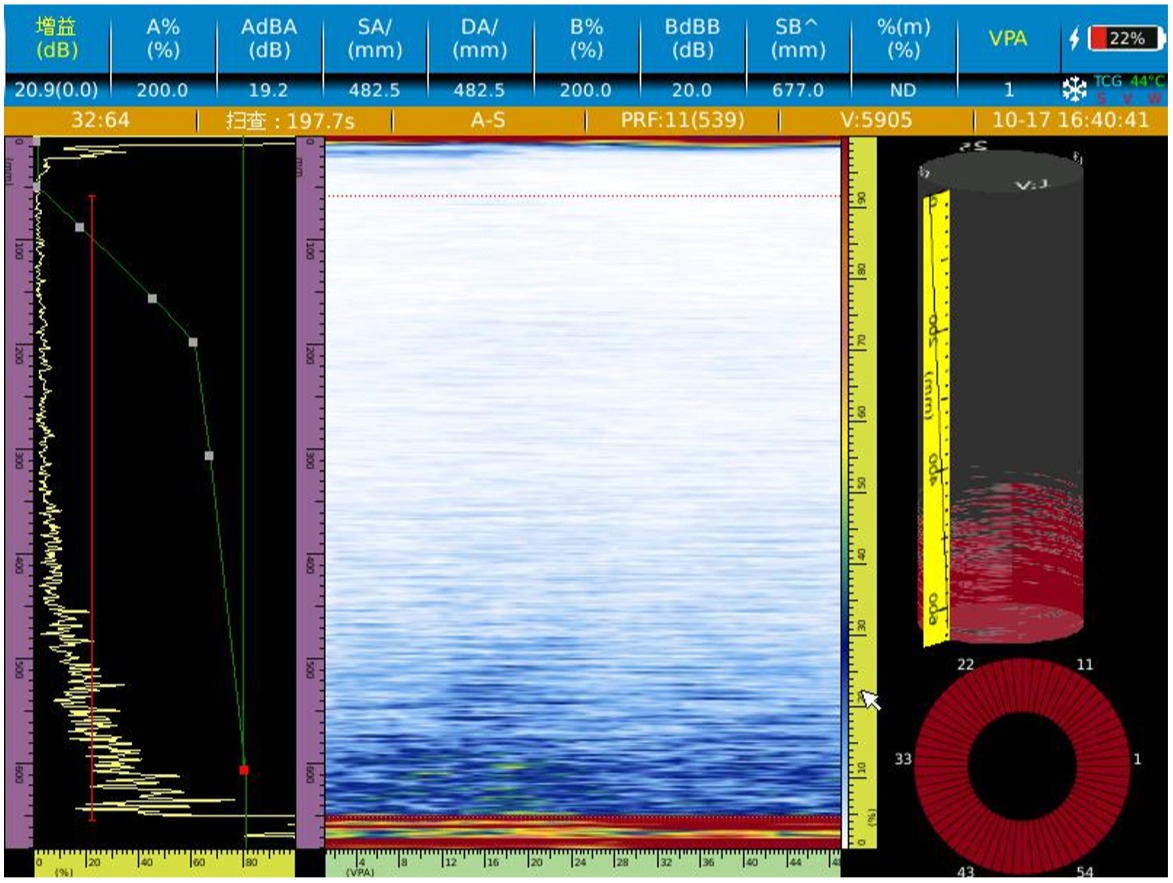

Our company was commissioned by a certain wind turbine blade factory to send two engineering and technical personnel to the site to inspect the wind turbine bolts. The on-site inspection is shown in the following figure:

The schematic diagram of the detection effect is as follows:

summarize:

From the above detection effect diagram, it can be seen that except for the bottom wave display, the image in the detection area is very clear and the color is basically the same. There is no interference waveform display that appears during conventional ultrasonic testing methods such as clutter, sidewall interference waves, and inherent echoes; These are all attributed to the powerful software processing capabilities of G-SCAN200 and the characteristics of phased array real-time focusing; Compared to other phased array devices at present, GSCAN200 performs more comprehensively in bolt detection, with clear effects, simple operation, and faster detection efficiency.