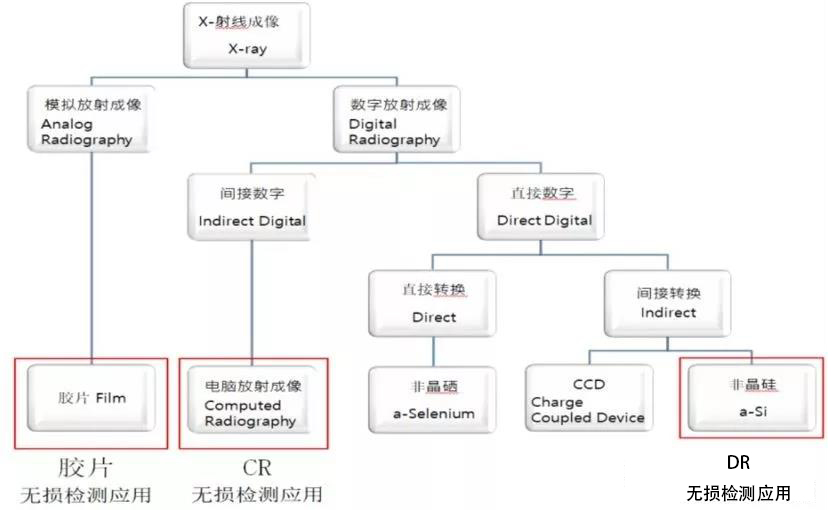

What is the difference between DR, CR, and film imaging?

1、 Imaging Principles

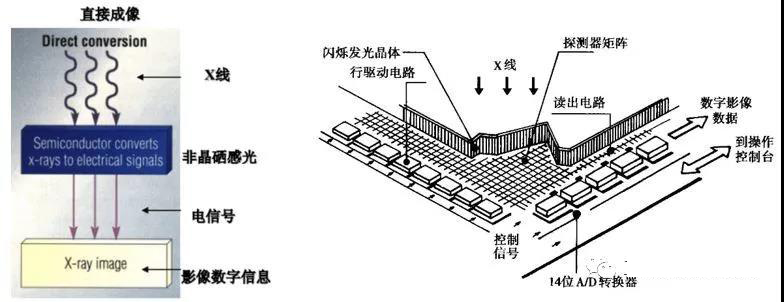

(1) DR is a direct conversion technology for X-rays, which uses flat panel detectors to receive X-rays. Flat panel detectors include CCD, amorphous silicon, amorphous selenium, and other types. The crystal circuit covered by the detector directly converts X-rays into digital current.

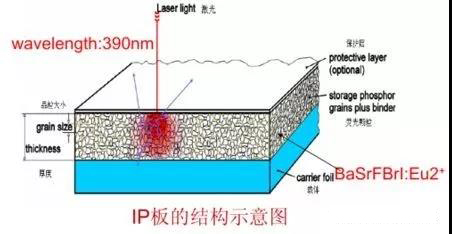

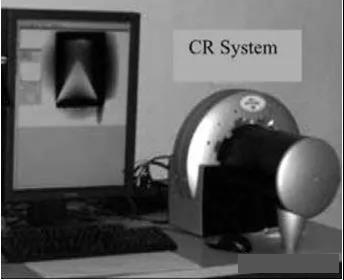

(2) CR is an indirect conversion technology for X-rays, which uses an image board as an X-ray detector. The image board immediately emits fluorescence after being irradiated by X-rays. During this process, nearly half of the energy of X-rays is lost, and residual X-ray intensity changes in spatial images are stored in the form of latent images. The latent image signal decays over time. When the scanner scans the image board, the latent image signal is converted into visible light by laser and sent to the computer for imaging through the photoelectric system.

(3) X-ray film imaging technology is the process of X-ray irradiation on the emulsion layer of the film, where the silver halide crystals inside the emulsion layer undergo chemical reactions and coalesce with adjacent silver halide crystals that have also been irradiated by X-ray, depositing on the film and leaving an image. The more light the emulsion layer receives, the more crystals will coalesce together. The less light the emulsion layer receives, the less changes and coalescence of the crystals will occur. Without light falling on the emulsion, there will be no crystal changes or coalescence. From this, different images are obtained.

二、 Image quality

(1) Resolution

• Due to its own structure, the CR system scatters phosphorus particles in the image board when exposed to X-ray radiation, causing latent image blurring. More seriously, during the process of reading out the image, the excitation of the scanner generates scattering when penetrating the deep part of the image board, forming stimulated fluorescence along the path, blurring the image and reducing its resolution.

• The DR system does not have optical blurring, and its clarity is mainly determined by pixel size. High spatial resolution, wide dynamic adjustable range, and rich image post-processing functions can achieve satisfactory diagnostic results.

• The DR system does not have optical blur, and its clarity is mainly determined by pixel size. High spatial resolution, wide dynamic adjustable range, and rich image post-processing functions can achieve satisfactory diagnostic results The size of silver iodide particles in high-quality film imaging can reach tens of micrometers or even smaller, so the film can achieve very high resolution.

(2) Exposure tolerance

Compared to X-ray film imaging technology, CR and DR have a wide dynamic range and tolerance due to the use of digital technology. However, the DR system allows for technical errors in photography and can obtain good images even in situations where conditions are difficult to master.

(3) Noise

There are many noise sources in the CR system, including structural noise of the image trigger, fluctuations introduced in the conversion and detection of X-ray photons, laser power drift, laser beam position drift, probability fluctuations of laser beam image trigger emission, and noise in the electronic chain.

The noise in the DR system is mainly structural noise, but since DR can automatically restore the detector array before directly obtaining the image, it greatly reduces structural noise. In contrast, the signal-to-noise ratio of DR is much higher than that of CR.

3、 Exposure dose

The DR system can directly obtain digital image data, while the CR system uses residual latent images to generate images, and the signal decays over time. Therefore, compared to DR and X-ray film imaging technologies, the X-ray quantum conversion rate (DQE) of CR is relatively low, and the exposure dose requirement is high.

4、 Comparison of workflow

(1) To generate an image in the CR system, the IP board needs to be exposed first, and then read out by the scanner. The entire process requires multiple steps and takes a long time.

(2) In the DR system, images can be obtained within 40 seconds after exposure, and the detector can be fixed inside the device, eliminating the need for technicians to move the detector, reducing labor intensity, saving time, and improving work efficiency.

(3) The image formation of film imaging consists of three stages: development, fixation, and visible image formation, which can be completed by manual washing or by a film developing machine.

5、 Network integration

Both CR and DR systems obtain digital images and can be connected to the internet. But DR is a direct conversion technology, and the integrated DICOM3.0 standard protocol makes DR's network integration characteristics stronger. DR technology has revolutionized conventional projection X-ray imaging, surpassing CR and X-ray film imaging in many aspects.

6、 Image storage

Traditional film preservation, management, and retrieval require a significant amount of manpower, material resources, and time. In addition, film will gradually deteriorate with increasing storage time, resulting in a decrease in image quality. CR and DR digital images can be managed in a digital electronic manner using massive computer storage, eliminating the need for a large and difficult to maintain film library.

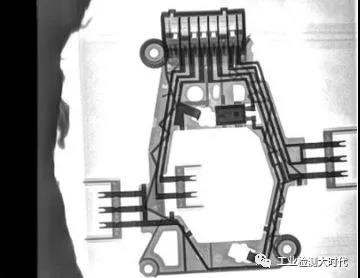

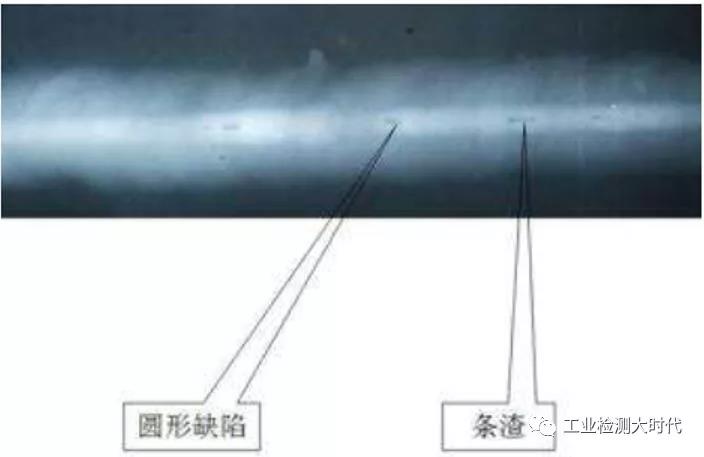

7、 Defect judgment

The evaluation of film imaging technology relies on film evaluators. This method is simple, but labor-intensive, subjective, and inconsistent. At present, the vast majority of weld defect inspections, including film imaging and digital imaging, use manual judgment, and the use of automatic recognition technology for general defect detection is not yet mature enough. However, in industries such as PCB boards, aluminum wheels, and lithium batteries, automatic defect detection systems improve product consistency and quality assurance.

8、 Equipment cost

For large enterprises, the cost of purchasing digital imaging systems is relatively high, but the cost of saving film in two years or even one year is equivalent to that of digital imaging systems. In the long run, the cost of adopting digital imaging is much lower than the cost of film.

9、 Environmental protection

Both CR and DR eliminate the pollution of industrial heavy metals and the generation of harmful wastewater during film processing, which is beneficial for environmental protection.