Welding seam inspection of high-density polyethylene (PE) plastic pipes

1. Background

High density polyethylene (PE) pipelines have the characteristics of light weight, hygiene and safety, low water flow resistance, energy saving, metal saving, improved living environment, long service life, safety and convenience, and are favored by the pipeline engineering industry. In recent years, driven by the rapid development of China's macro economy, plastic pipelines in China have experienced rapid development against the backdrop of the rapid development of chemical and building materials. In 2010, the national production of plastic pipelines exceeded 8 million tons. Plastic pipelines have many advantages over traditional metal pipes and concrete pipes in multiple fields, and therefore have been recommended for use in many regions.

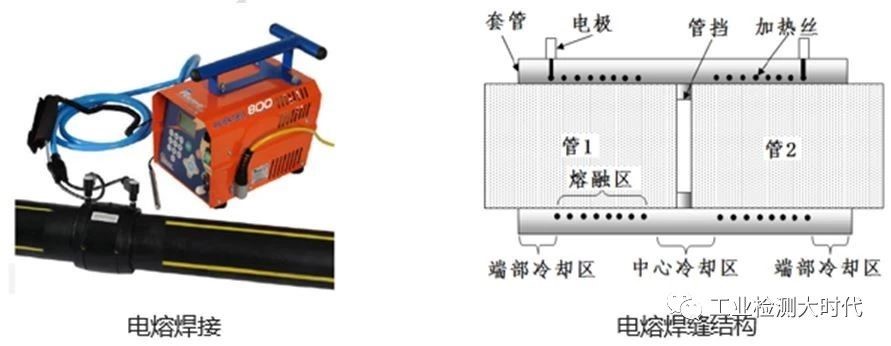

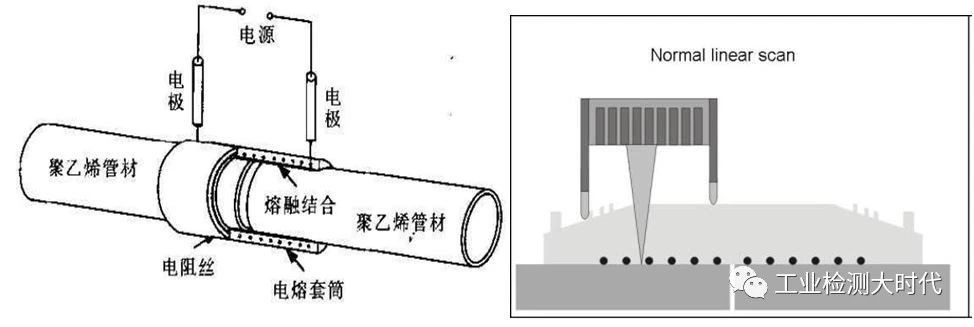

Electric fusion connection process: Electric fusion connection is an advanced method of connecting the inner wall of the pipe fitting and the surface of the pipeline by using a specialized pipe fitting embedded with an electric heating wire. After connecting to the power supply, the electric heating wire is generated, which can melt the inner wall of the pipe fitting and the surface of the pipeline.

The existing available ultrasonic testing methods include TOFD and PAUT, both of which require the use of proprietary water injection wedges for local water coupling.

3.1 Electric fusion welding seam

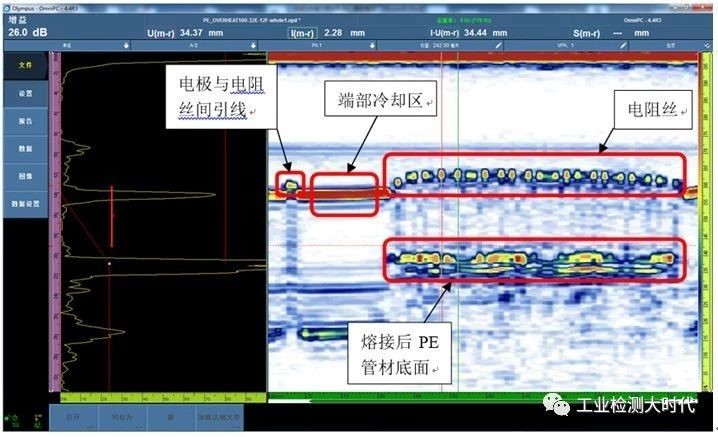

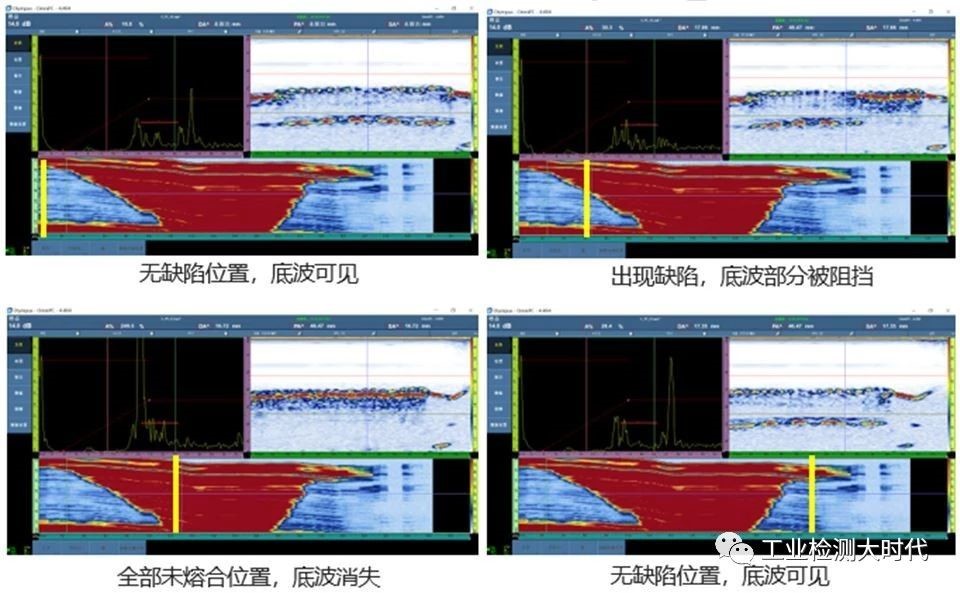

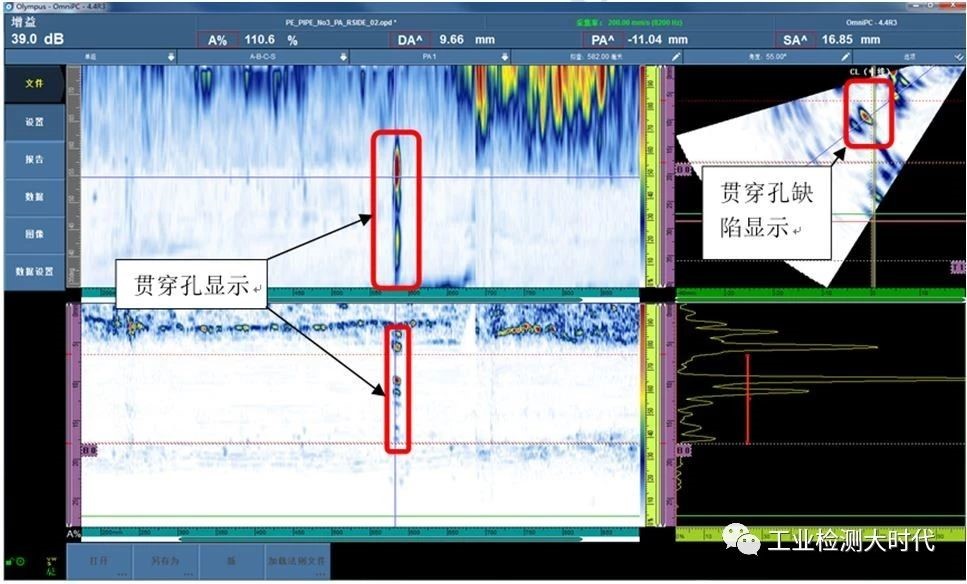

For plastic pipes welded by electric fusion, the phased array probe can be placed on the outer wall of the pipe fitting, so that the position and morphology of the resistance wires inside the pipe fitting can be seen. If there are other signals besides the resistance wire signal, it can be considered as fusion defects.

![[CropImg]8.jpg](/d/file/p/2020-01-08/b470f9ed5e4ad69a28a0d552946fc9c3.jpg)

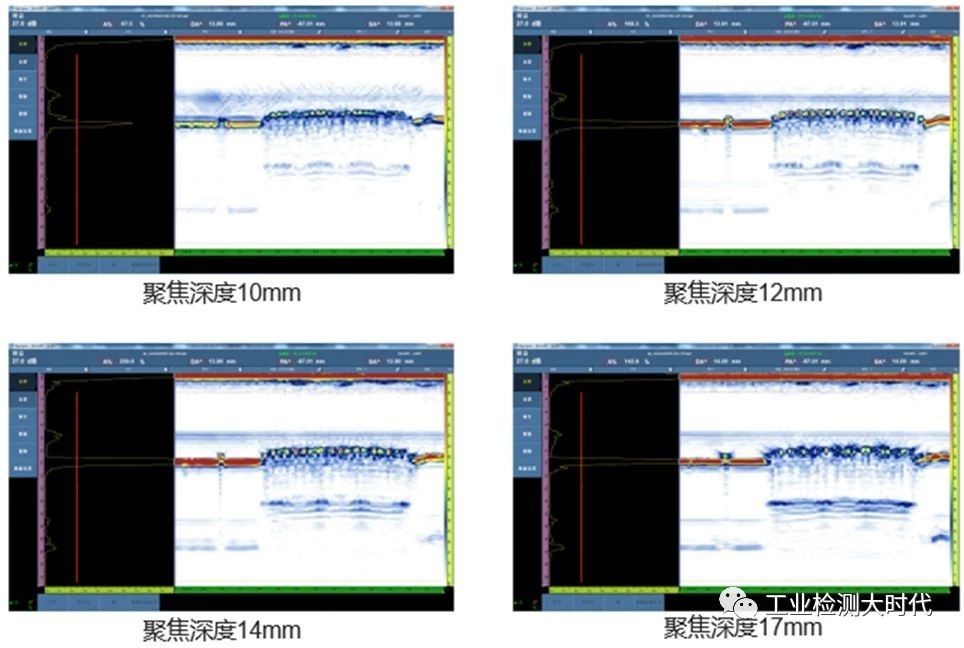

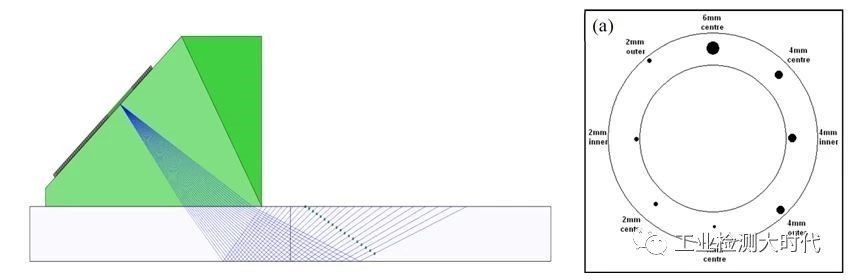

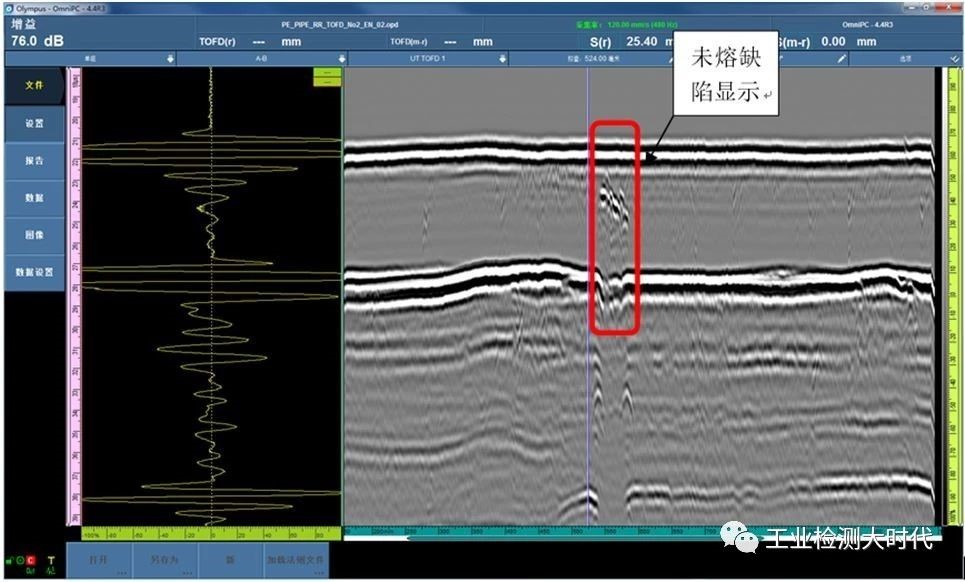

Using phased array technology to detect hot melt welds, a flat bottom hole is made horizontally at the end of the PE pipe to simulate unfused defects in the hot melt weld.

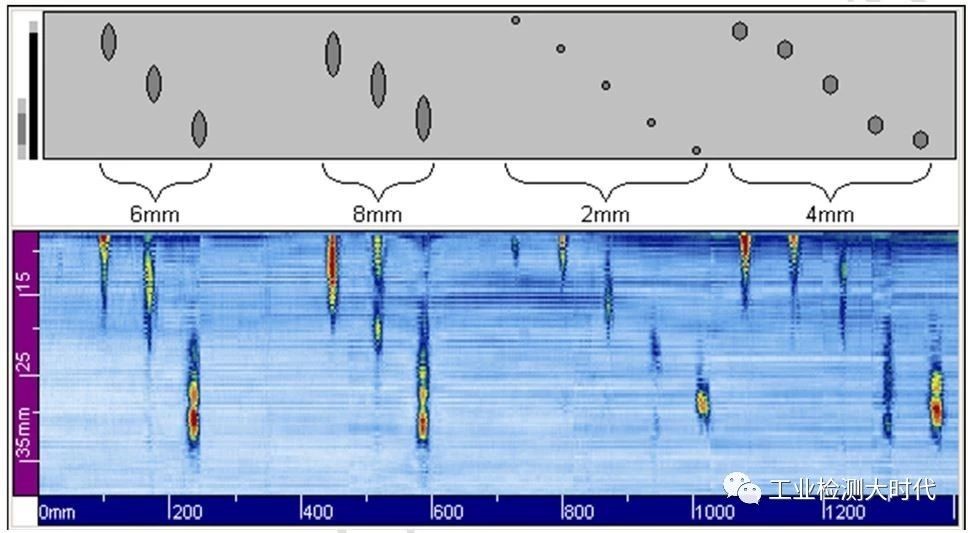

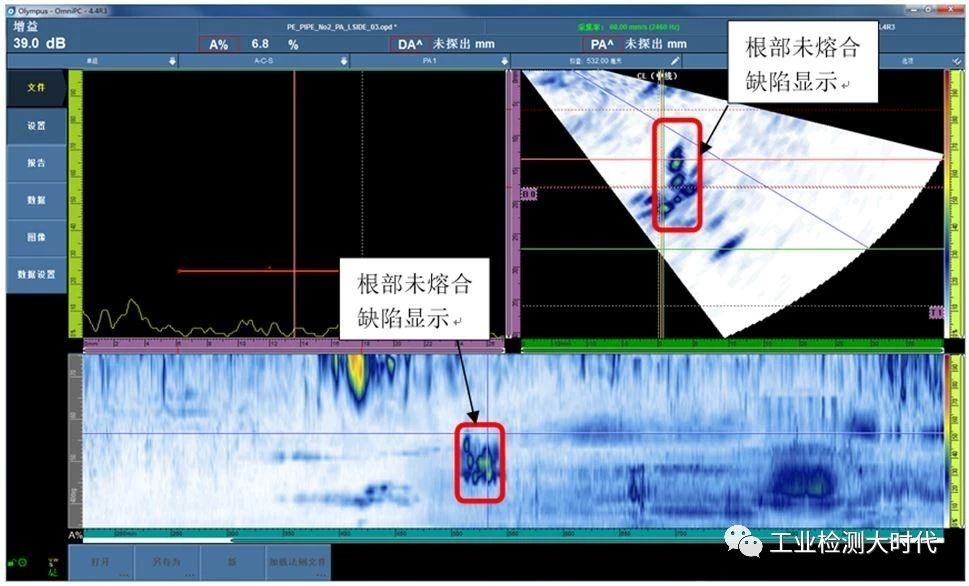

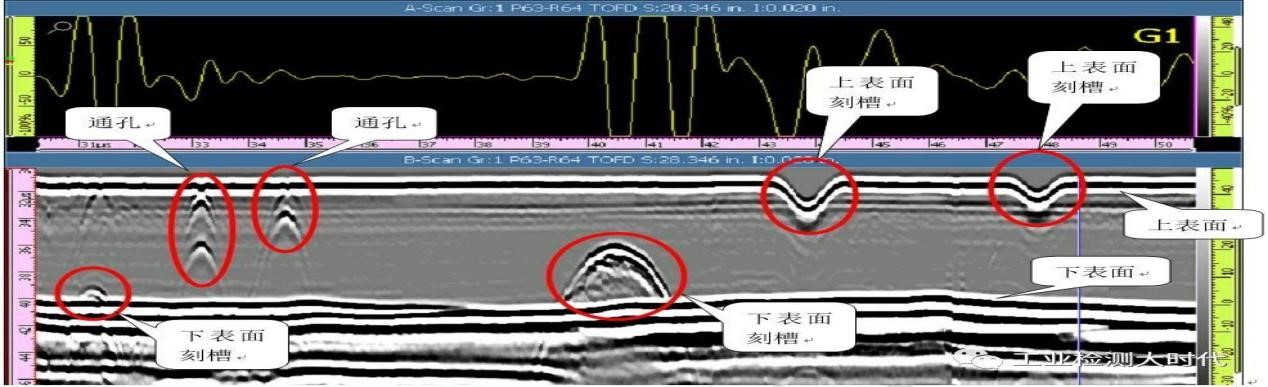

Use TOFD detection technology to detect hot melt welded pipes. Below are TOFD images of grooves on the upper and lower surfaces and drilled holes in the middle. The defect signals in different parts of the weld seam are clearly visible in the image, and the material noise inside the plastic is relatively low, with a high signal-to-noise ratio.

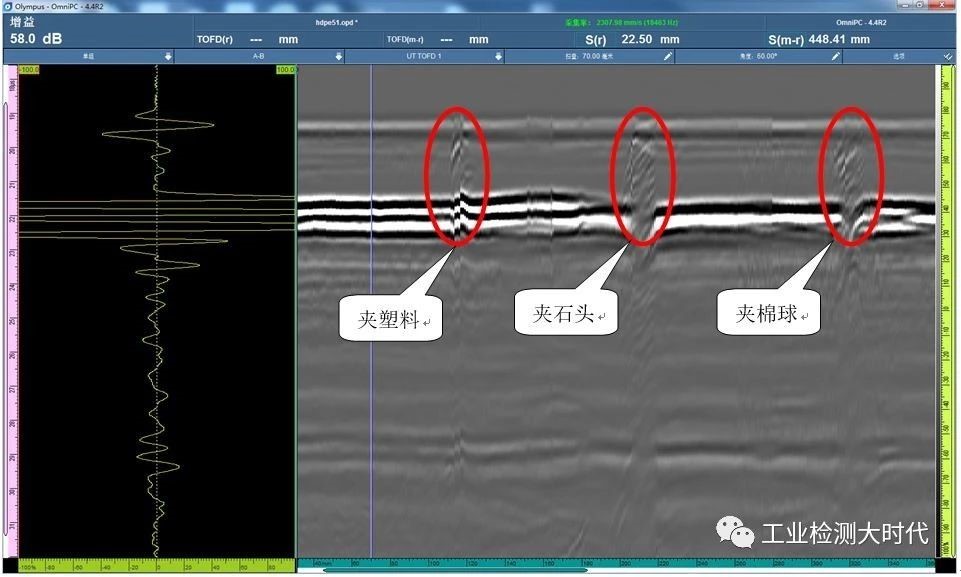

The use of ultrasonic phased array technology can detect unmerged defects in electric fusion welding welds, and can clearly display the signal of the resistance wire and the bottom wave signal. The use of TOFD combined with phased array technology can detect unmerged defects in hot melt welded joints, especially the strong detection ability of TOFD for unmerged defects in the vertical direction;

In the current era, domestic and international technologies are constantly emerging, and technological innovation is constantly emerging. Mature technologies such as PE pipe testing, corrosion testing of steel pipes through insulation layers, testing of composite materials and fiberglass, bolt stress and internal defect testing, etc., have already been developed to achieve the expected results of testing; We, Ge Yu Technology (Shanghai) Co., Ltd., are committed to cutting-edge trends, delving into new foreign technologies and combining them with domestic technical characteristics and the needs of owners. We can provide targeted testing plans to users, meeting the different needs of different customers. Because of our professionalism, we are trustworthy. We will always serve the public with a devout heart and give back to society.