CTS-PA322T real-time 3D fully focused bolt dedicated detector

1. System Introduction

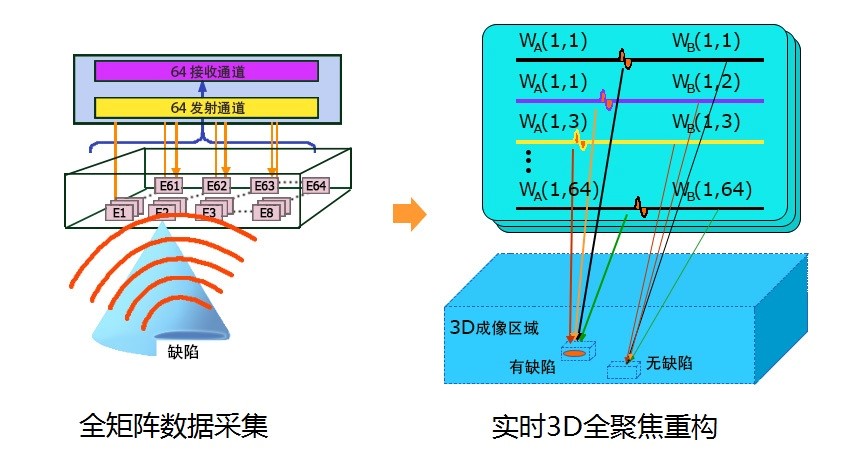

CTS-PA322T is a new 64 channel fully parallel phased array fully focused (TFM) real-time ultrasound imaging detection system independently developed by our company. The system collects real-time Full Matrix (FMC) data inside the material and utilizes high-speed hardware imaging technology based on signal processing chips to achieve high-precision real-time phased array 2D/3D full focus (TFM) imaging detection of metal and non-metallic materials. The first industrial phased array RF radio frequency metadata platform can directly process complete raw data through computer. The system uses 3D imaging to detect bolts or pins, with graphics that can be rotated and observed. Defect identification is simple, detection speed is fast, and the average detection time for a bolt is 2 seconds. The detection results are reliable and damage is easy to observe. Operators do not need to master professional skills. They can open the instrument and connect the probe according to the prescribed method, and only need one day of operation training to master the flaw detection method.

2. Features of bolt detection function:

The instrument can achieve complete in-service testing of bolts (i.e. testing without removing bolts), and can directly determine whether bolts have broken or cracked based on images;

The detector can be used to detect bolts of different specifications and models (including tower bolts, yaw bolts, connecting bolts between the main shaft and the hub, blade inner and outer pitch bolts, etc.) for the entire fan. The high-strength bolt specifications are M20 to M56, and the longest bolt size is 1000mm. The bolt types include outer hexagonal bolts, inner hexagonal bolts, and double head studs;

The calibration interface process of the detector is simple, with calibration functions such as sound speed, zero point, TCG, and gain function;

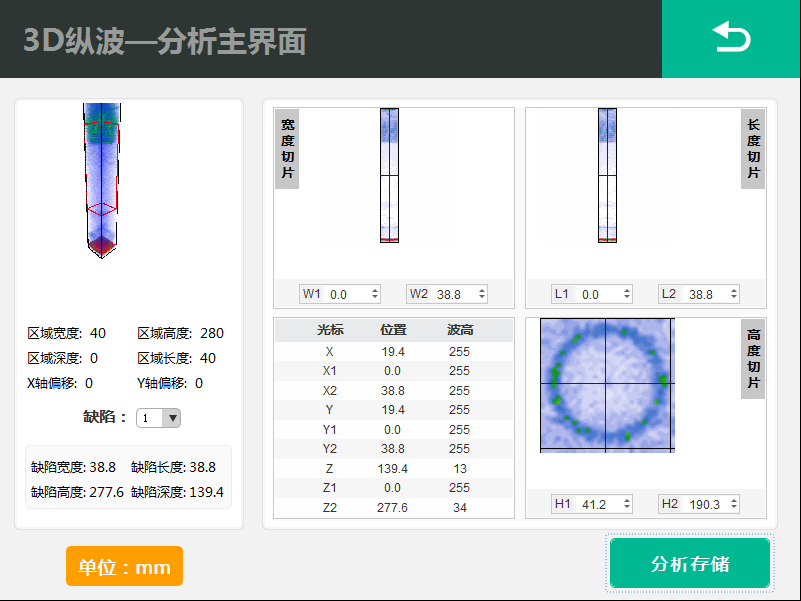

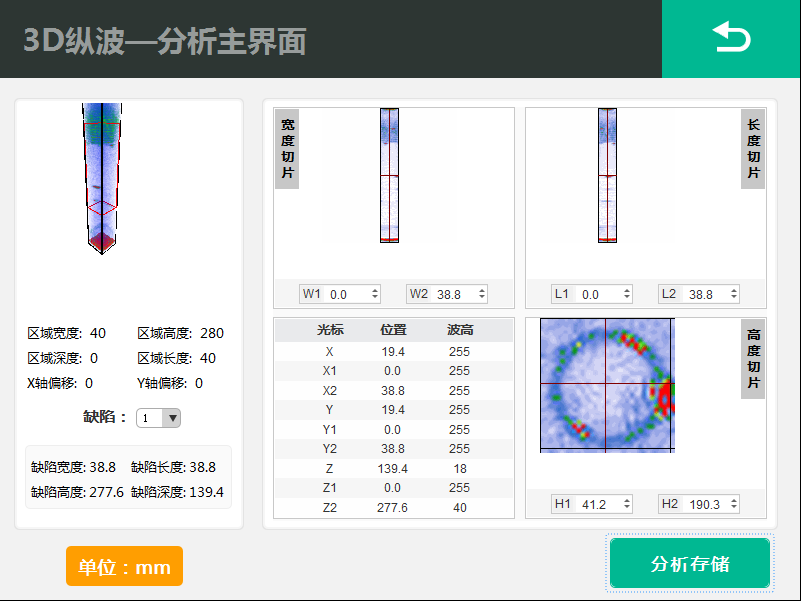

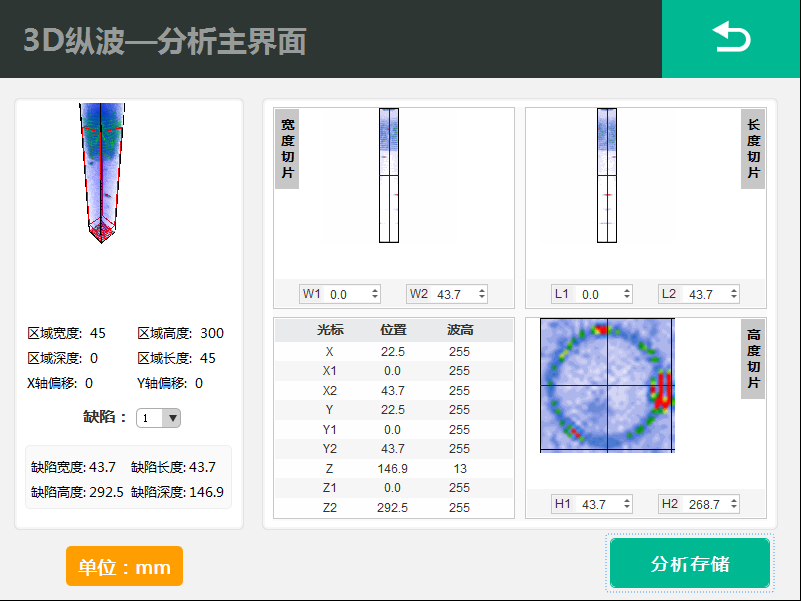

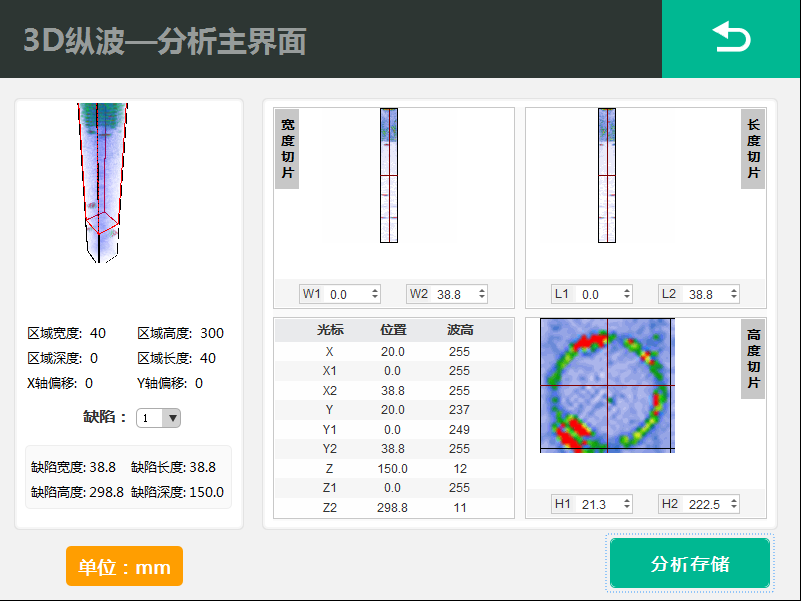

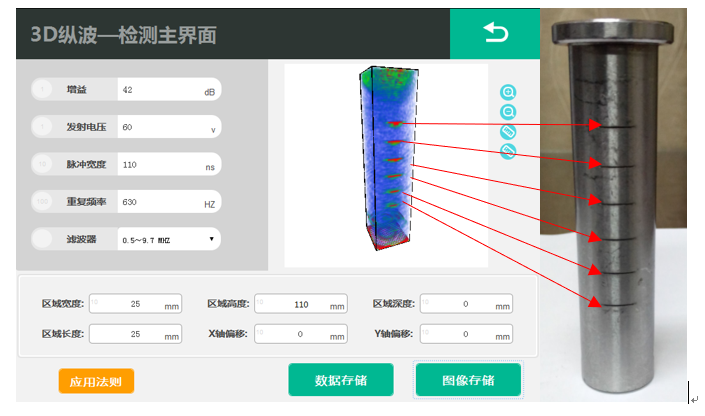

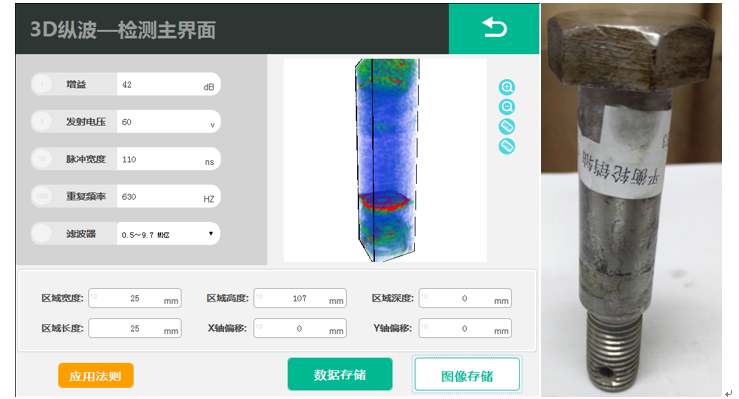

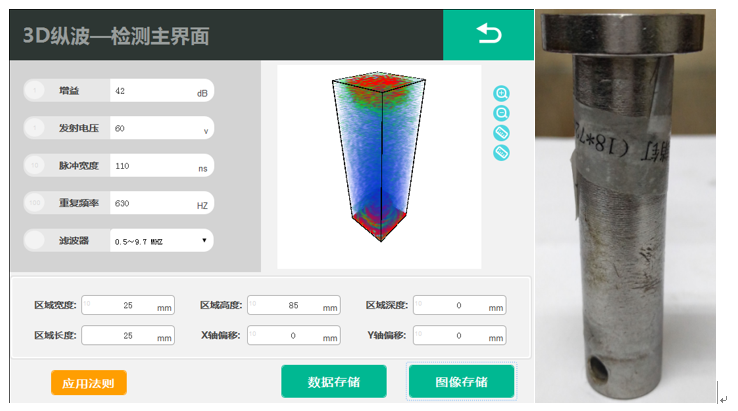

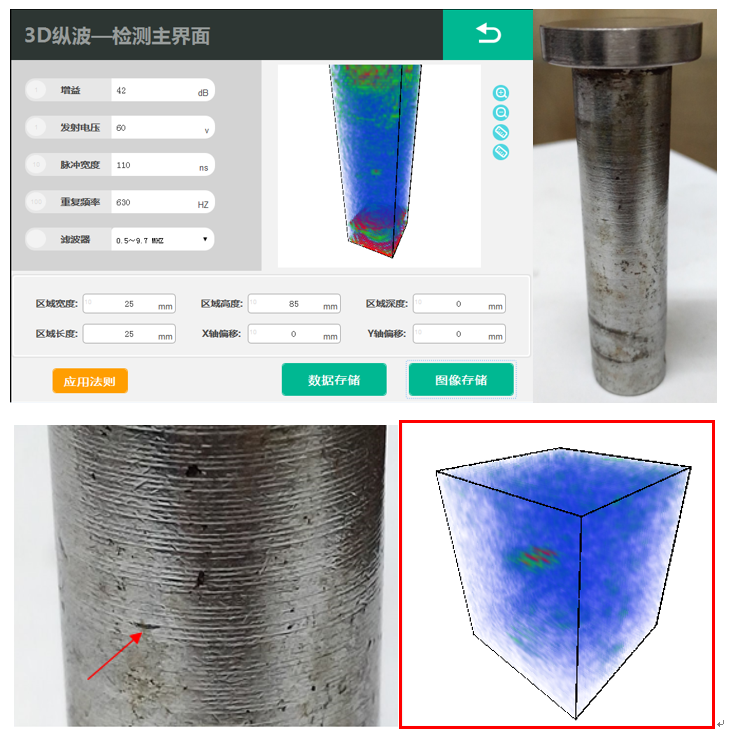

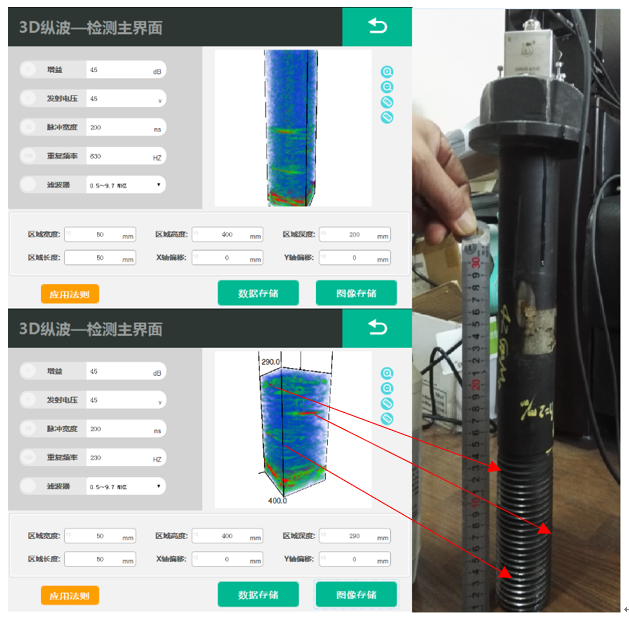

The detector is easy to operate and has intuitive imaging results. Can directly input bolt specifications and complete real-time 3D imaging of bolts. And it is possible to rotate and translate the 3D image to view defects. And provide the main view, side view, and cross-sectional view of the inspection bolts. Different views can display bolt defect information such as location, size, and degree of defect;

3. System functional characteristics:

Based on the fully focused (TFM) reconstruction algorithm model, high-speed hardware imaging technology based on FPGA operation is used to calculate the TFM image results in real-time, with an image refresh rate of up to 50 frames/s.

L has 64 fully parallel phased array hardware channels, which can collect raw Full Matrix (FMC) data of up to 64 * 64 A-type waves in real-time, with a maximum data collection depth of up to 2m.

Support real-time, wide-range, fully focused (TFM) imaging detection of large workpieces such as railway rail welds, locomotive vehicle rims, and axles.

Support high-precision real-time full focus (TFM) imaging detection of aircraft skin composite thin plate workpieces.

For different detection applications, multiple fully focused (TFM) imaging detection modules are built-in. Simply input parameters such as probes, wedges, and workpieces in the process design interface to easily access the main interface of TFM detection for detection.

According to the specific needs of users in actual detection applications, a dedicated Total Focused (TFM) detection module can be customized and developed.

The 3D Longitudinal Wave Fully Focused (TFM) module is based on a two-dimensional array probe and adopts a single reflection longitudinal wave fully focused (TFM) mode to visually detect defects such as through-holes, bubbles, slag inclusions, and other types of direct reflection inside the material.

The multi-layer material longitudinal wave fully focused (TFM) module adopts a single reflection longitudinal wave fully focused (TFM) mode to detect the lack of adhesion and poor adhesion of multi-layer layered materials. It can also be used to detect direct reflection type defects inside each layer of material, such as through holes, bubbles, slag inclusions, etc.

The use of diagonal data from the original full matrix (FMC) can achieve synthetic aperture SAFT imaging of the tested material.

The principle of SAFT imaging technology based on Full Matrix Data (FMC) can achieve fast C-scan imaging based on SAFT technology.

4. System performance indicators:

|

脉冲 发生器 |

发射电压 |

双极性方波,45 V ~ 100 V可调,步进1V、10 V |

|

脉冲宽度: |

10 ~ 600 ns,步进1ns、10 ns |

|

|

接收器 |

带宽: |

0.5 ~15MHz |

|

增益范围: |

0 ~ 55 dB,步进1dB 、10dB |

|

|

滤波器: |

低、中、高3档 |

|

|

数据处理 |

数字化率: |

62.5 MHz,10 bit |

|

输入阻抗: |

50Ω |

|

|

嵌入处理器: |

大型FPGA嵌入,大数据的实时硬件运算处理 |

|

|

聚焦法则: |

65536个法则 |

|

|

接收延迟: |

0~40 μs,精度2.5ns |

|

|

系统 |

通道配置: |

全并行64*64 |

|

功耗: |

约50 W |

|

|

运行平台: |

Windows7系统以上 |

|

|

数据传输: |

100M/1000M 以太网 |

|

|

尺寸: |

410×120×280mm |

|

|

重量: |

11Kg含电池 |

|

|

输入输出 |

电脑配置 |

USB 3.0接口4个 |

|

HDMI高清视频接口1个 |

||

|

LAN千兆网口2个 |

||

|

Rs232串口调试口1个 |

||

|

VGA视频信号接口1个 |

||

|

相控阵主机配置 |

I-PEX相控阵探头接口1个 |

|

|

LAN千兆网口1个 |

||

|

I/O输出口1个 |

||

|

USB 2.0接口2个 |

||

|

ENCONDER编码器接口1个 |

CTS-PA322T is a new 64 channel fully parallel phased array fully focused (TFM) real-time ultrasound imaging detection system independently developed by our company. The system collects real-time Full Matrix (FMC) data inside the material and utilizes high-speed hardware imaging technology based on signal processing chips to achieve high-precision real-time phased array 2D/3D full focus (TFM) imaging detection of metal and non-metallic materials. The first industrial phased array RF radio frequency metadata platform can directly process complete raw data through computer. The system uses 3D imaging to detect bolts or pins, with graphics that can be rotated and observed. Defect identification is simple, detection speed is fast, and the average detection time for a bolt is 2 seconds. The detection results are reliable and damage is easy to observe. Operators do not need to master professional skills. They can open the instrument and connect the probe according to the prescribed method, and only need one day of operation training to master the flaw detection method.

2. Features of bolt detection function:

The instrument can achieve complete in-service testing of bolts (i.e. testing without removing bolts), and can directly determine whether bolts have broken or cracked based on images;

The detector can be used to detect bolts of different specifications and models (including tower bolts, yaw bolts, connecting bolts between the main shaft and the hub, blade inner and outer pitch bolts, etc.) for the entire fan. The high-strength bolt specifications are M20 to M56, and the longest bolt size is 1000mm. The bolt types include outer hexagonal bolts, inner hexagonal bolts, and double head studs;

The calibration interface process of the detector is simple, with calibration functions such as sound speed, zero point, TCG, and gain function;

The detector is easy to operate and has intuitive imaging results. Can directly input bolt specifications and complete real-time 3D imaging of bolts. And it is possible to rotate and translate the 3D image to view defects. And provide the main view, side view, and cross-sectional view of the inspection bolts. Different views can display bolt defect information such as location, size, and degree of defect;

3. System functional characteristics:

Based on the fully focused (TFM) reconstruction algorithm model, high-speed hardware imaging technology based on FPGA operation is used to calculate the TFM image results in real-time, with an image refresh rate of up to 50 frames/s.

L has 64 fully parallel phased array hardware channels, which can collect raw Full Matrix (FMC) data of up to 64 * 64 A-type waves in real-time, with a maximum data collection depth of up to 2m.

Support real-time, wide-range, fully focused (TFM) imaging detection of large workpieces such as railway rail welds, locomotive vehicle rims, and axles.

Support high-precision real-time full focus (TFM) imaging detection of aircraft skin composite thin plate workpieces.

For different detection applications, multiple fully focused (TFM) imaging detection modules are built-in. Simply input parameters such as probes, wedges, and workpieces in the process design interface to easily access the main interface of TFM detection for detection.

According to the specific needs of users in actual detection applications, a dedicated Total Focused (TFM) detection module can be customized and developed.

The 3D Longitudinal Wave Fully Focused (TFM) module is based on a two-dimensional array probe and adopts a single reflection longitudinal wave fully focused (TFM) mode to visually detect defects such as through-holes, bubbles, slag inclusions, and other types of direct reflection inside the material.

The multi-layer material longitudinal wave fully focused (TFM) module adopts a single reflection longitudinal wave fully focused (TFM) mode to detect the lack of adhesion and poor adhesion of multi-layer layered materials. It can also be used to detect direct reflection type defects inside each layer of material, such as through holes, bubbles, slag inclusions, etc.

The use of diagonal data from the original full matrix (FMC) can achieve synthetic aperture SAFT imaging of the tested material.

The principle of SAFT imaging technology based on Full Matrix Data (FMC) can achieve fast C-scan imaging based on SAFT technology.

4. System performance indicators:

6. Practical application of bolt inspection

Due to the fact that the CTS-PA322T system is based on a two-dimensional array probe to collect real-time spatial 3D information from different angles and perform real-time hardware 3D full focus, this imaging mode is very suitable for real-time imaging detection of bolts, pins, and other workpieces. Based on different sizes of bolts, we can use array probes of different sizes and combine them with acoustic impedance matching delay blocks of different materials to achieve effective real-time 3D detection of various sizes of bolts.

L Wind power bolt inspection:

1) Manual grooving of various types of bolts:

2)自然缺陷螺栓:

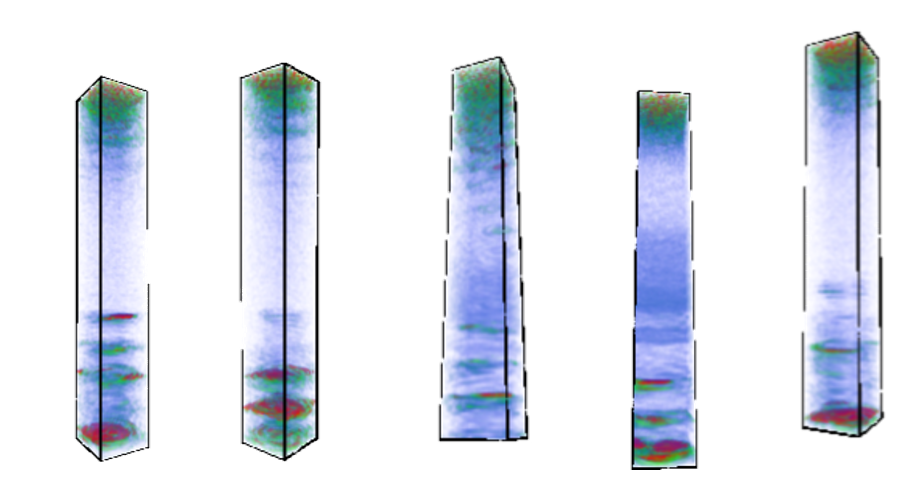

The 5 bolts shown in the above figure are the inner pitch bolts of 5 blades with natural defects (fractures and cracks) detected in a certain wind farm and their inspection results.

l Other bolt inspection::

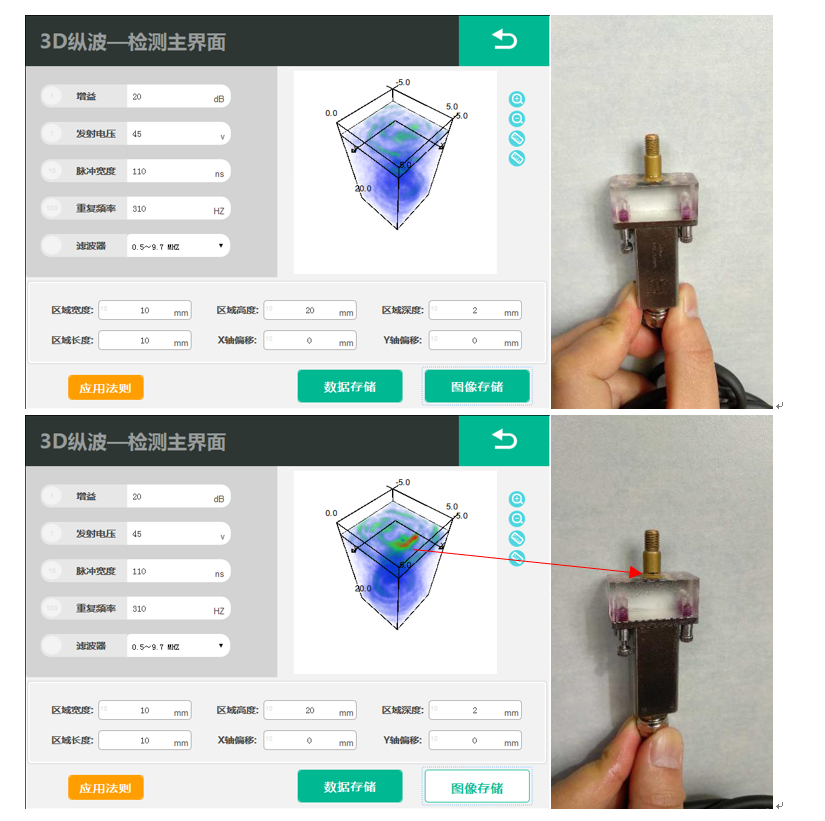

1)Copper bolts - artificial defects

The bolt material is brass, with a length of 18mm and a diameter of 6mm. One has a 1mm deep artificial wire cutting crack, while the other has no cracks.

2)High strength alloy steel bolts - artificial defects

The bolt material is grade 12.9 high-strength alloy steel, with a length of 100mm and a diameter of 30mm. Two 2mm deep artificial wire cutting cracks were machined at the bottom of the threads with a circumferential spacing of 120 ° at a depth of 50mm and 80mm, respectively.

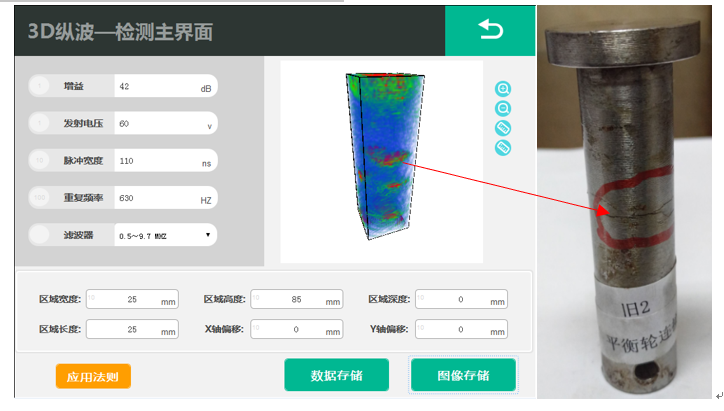

3)Balancing wheel connecting pin - artificial defect

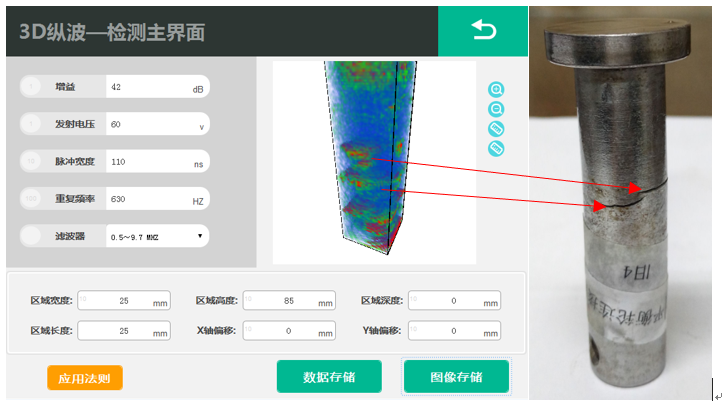

4)Anchor bracket connection pin - artificial defect

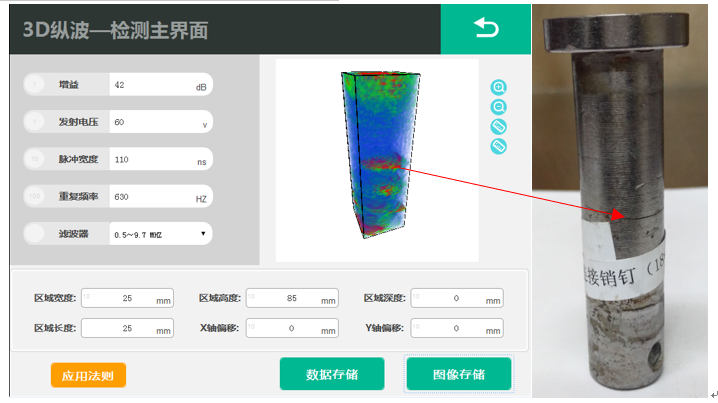

5)Balance wheel pin shaft - manual defect

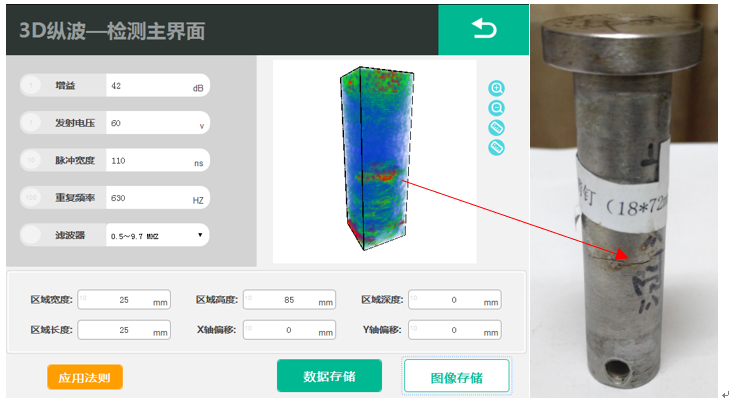

6)Anchor bracket connection pin - no defects

7)Anchor bracket connection pin - no defects

8)Balancing wheel connecting pin 1- no defects

9)Balancing wheel connecting pin 6- natural defect

10)Balancing wheel connecting pin 2- natural defect

11)Balancing wheel connecting pin 3- natural defect

13)Balancing wheel connecting pin 4- natural defect

14)平衡轮连接销钉5——自然缺陷

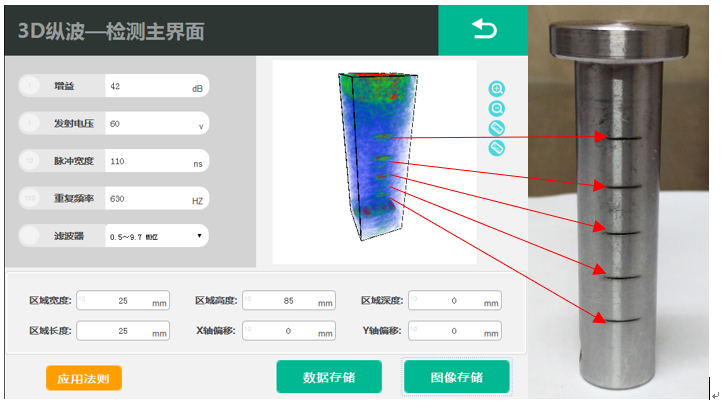

16)High strength bolts for crane slewing mechanism - artificial defects

The bolt has a length of 400mm and a diameter of 50mm. Three 2mm deep artificial wire cutting cracks were machined at the bottom of the threads with a circumferential spacing of 120 ° at depths of 300mm, 320mm, and 340mm.