Testing Technology of Concrete Building Sleeve Grouting (Digital DR Ray) Imaging Method

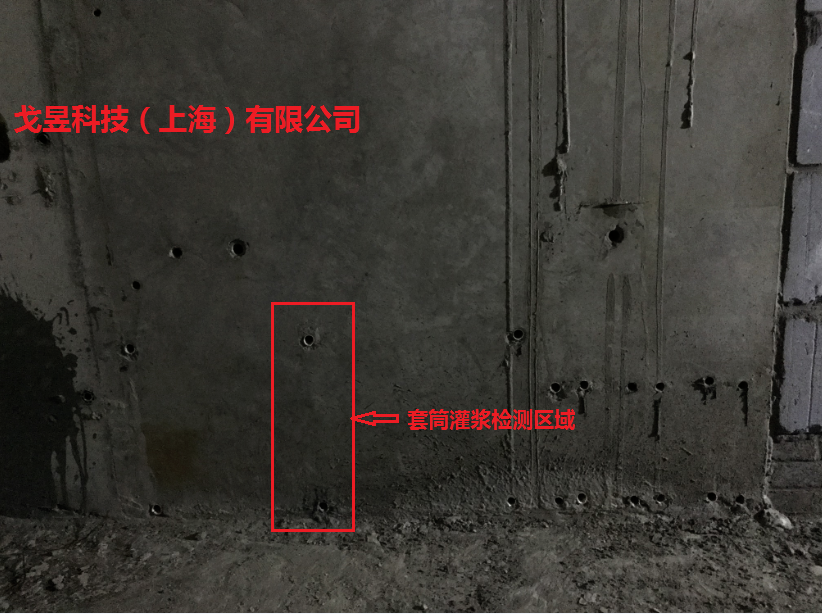

The planning for prefabricated buildings has been intensively introduced since 2015. At the end of 2015, the "Evaluation Standards for Industrial Buildings" was issued, and it was decided to comprehensively promote prefabricated buildings nationwide in 2016, achieving breakthrough progress; On November 14, 2015, the Ministry of Housing and Urban Rural Development issued the "Outline for the Modernization of the Construction Industry", which plans to have prefabricated buildings accounting for over 20% of new buildings by 2020 and over 50% of new buildings by 2025. So new requirements have been put forward for testing technology. Ge Yu Technology's technical team has conducted a large number of non-destructive testing experiments (digital DR testing) on various sleeve grouting samples, and obtained the following experience for reference:

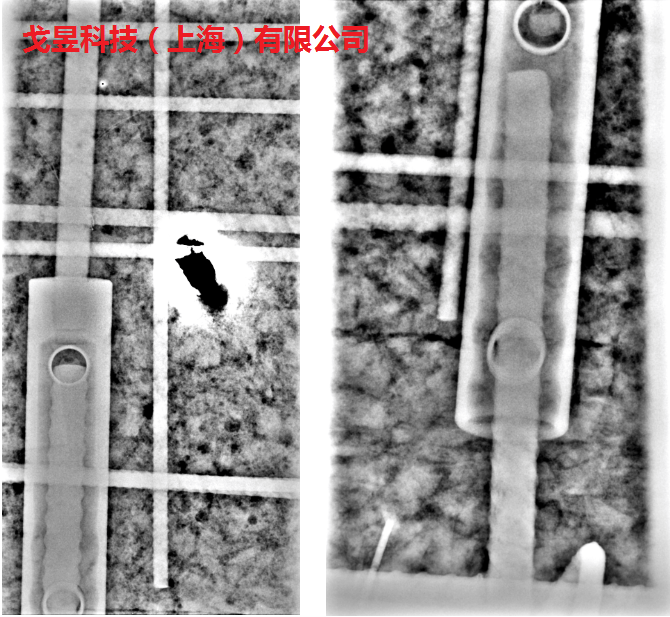

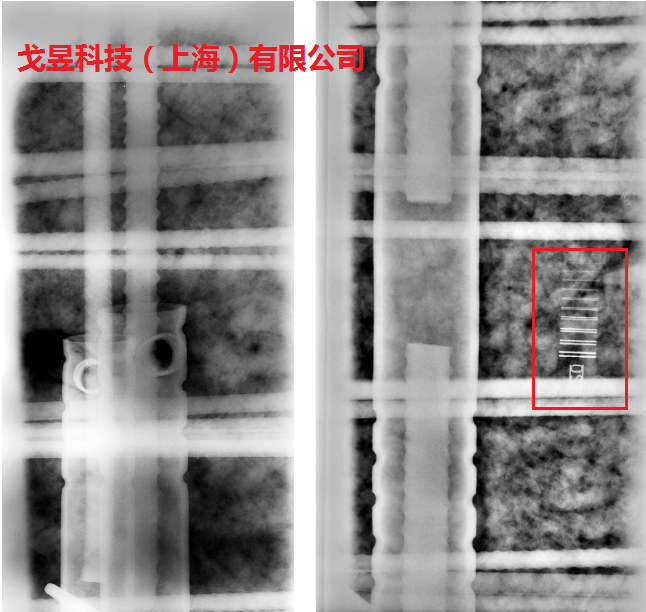

The reliability of sleeve grouting connection is mainly controlled by two indicators: the length of the steel bar inserted into the sleeve, and the fullness of the grouting. Portable DR testing technology is currently the most intuitive and convenient non-destructive testing technology for the above two indicators, with reliable results. The image is clear, the internal grouting saturation is clear at a glance, and the position of the steel bars is clear.

2.1 The penetration ability of the X-ray machine should be strong: the 300kV constant pressure portable function of the microfocus can meet the requirements of penetrating 200-300mm concrete.